Viscom Inc.

Suite 500

Duluth, GA 30096

Software simplifies AOI programming and control.

EasyPro user interface for circuit board inspection systems provides Inspection mode, Programming mode, and Service mode. All necessary programming tools are available continuously, without having to activate them separately. Interface integrates program optimization with parameter settings and editing of inspection pattern. File import from SPC software into programming software allows control...

Read More »

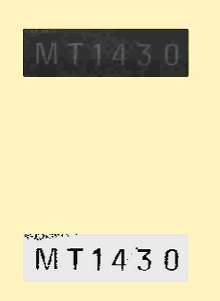

Software equips inspection systems with OCR feature.

Independent of script fonts, software includes OCR (optical character recognition) feature that reads clear text and facilitates second source verification. OCR is used for placement verification, identification of version status, and information customization. Software also records serial numbers and component versions, allowing comparison with component labeling. Program recognizes all fonts...

Read More »Viscom Listed in 2018 World Market Leader Index

Hanover, February 2018 – Viscom AG has just been listed as World Market Leader Champion 2018 in the World Market Leader Index (WMFI) of the University of St. Gallen and Academy of German World Market Leaders. Viscom's inclusion among the World Market Leader Champions of 2018 brings yet another confirmation of the innovative inspection solutions offered by the company that are in demand around...

Read More »

Software simplifies AOI programming and control.

EasyPro user interface for circuit board inspection systems provides Inspection mode, Programming mode, and Service mode. All necessary programming tools are available continuously, without having to activate them separately. Interface integrates program optimization with parameter settings and editing of inspection pattern. File import from SPC software into programming software allows control...

Read More »

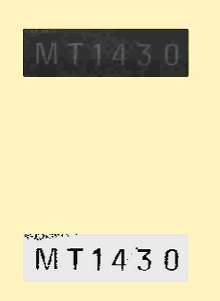

Software equips inspection systems with OCR feature.

Independent of script fonts, software includes OCR (optical character recognition) feature that reads clear text and facilitates second source verification. OCR is used for placement verification, identification of version status, and information customization. Software also records serial numbers and component versions, allowing comparison with component labeling. Program recognizes all fonts...

Read More »