WEIMA and Gamma Meccanica Join Forces in Plastics Recycling

WEIMA America has collaborated over the years with many manufacturers of plastics recycling machinery in order to perfect the perfect system for our customers. One of those manufacturers is Gamma Meccanica. WEIMA and Gamma Meccanica have more than 50 years of combined innovation, experience, and success in the plastics industry worldwide. There are many cases of collaboration between the two...

Read More »

Taskmaster-® Heavy Solids Shredder

The TASKMASTER-® TM 1600 is a powerful workhorse that can shred heavy solids in both gravity and liquid systems. Typical applications include containers, plastics, packaging, wood, paper, documents, electronic components, concession waste, sewage screenings, in-channel raw sewage, and more. Bulk volume is reduced up to 80%, significantly eliminating storage or disposal costs and aiding in the...

Read More »

Dual Mode Mobile Shredder offers max payload of 13,000 lb.

Featuring twin-screw angled compactor and moving floor loading system, Model MDX-1 switches between standard and high-security modes with touch of button, achieving throughputs up to 6,500 lb/hr and 2,500 lb/hr, respectively. Gripper TipperÃ-® retractable bin tunnel loading system allows for ground or curbside loading of any industry standard container, while Plus 1Ã-® micro-control...

Read More »

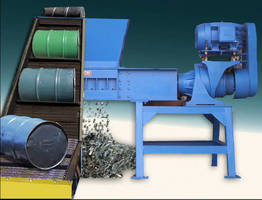

TASKMASTER-®TM2800-Shreds Steel Drums to Crumbs

The TASKMASTER TM2800 Shredder quickly shreds steel drums down to strips of metal for a major reduction in space. It also facilitates the recovery of the steel and/or the contents of the drums. These units provide fast and efficient destruction of a wide variety of bulk solids, quickly reducing bulk volume by up to 80%. With its powerful shredding action, this low speed, high torque shredder...

Read More »

Reshoring in Metal Stamping

This white paper provides an overview into the reshoring of metal stamping and other manufacturing processes.

Read More »

In-Line Disintegrator Reduces Tough Solids

The Super Shredder-® in-line disintegrator easily reduces tough solids directly in sludge or raw sewage lines. The unit combines unsurpassed grinding capabilities with streamlined, easy to maintain features. Its innovative design provides a high level of open area to fluid flow making the Super Shredder ideal for applications requiring a heavy duty size reduction processor that can handle high...

Read More »

Hard Drive Shredder is designed for fast, safe operation.

Mounted on casters for mobility, Jackhammer(TM) destroys computer hard drives, optical media, and any other electronic devices that can fit through its 10Ã-¾ x 2Ã-½ in. feeder-chute opening. Sawtooth hooked cutters, powered by 5 hp motor and high-torque mechanism, reduce items to 1Ã-½ in. shreds. Capable of chewing up 20+ HDDs/min with minimal noise and vibration, key-operated 54 x 50...

Read More »

Forget What You Think You Know About Shredder Grates: Updated Double Beam Design Is Both Tough and Efficient

PORTLAND, OR - APRIL 2009 - Gone are the days when a 4,000 to 6,000 horsepower shredder could get the job done. Current industry demands are putting big pressure on equipment - and operators - to process even the most unwieldy scrap with maximum efficiency and profitability. Customers are shredding materials that might have been unthinkable 10 years ago, says Columbia Steel Product Engineer Greg...

Read More »Batson Group, Inc. to Sell Recycling Machinery

Greenville, SC: Batson Group, Inc. is pleased to announce they have been chosen to represent Pallmann Industries, Inc., in the United States and Canada. Based in Clifton, New Jersey, Pallmann Industries, Inc., is a member of the Pallmann Maschinenfabrik GmbH Group of Companies (ZweibrÃ-¼cken, Germany). Batson will market their size-reduction and recycling systems. Founded in 1903, Pallmann is...

Read More »Paper Shredder provides jam-proof operation.

Including models PS-79Ci, SB-89Ci, and SB-99Ci, Intellishred(TM) Series eliminates jams and prevents overloads by calculating amount of paper being fed into machine. SafeSense(TM) technology disables shredders when sensing hands are too close to paper opening, while SilentShred(TM) technology features quiet motor that alleviates common shredder noise concerns. Machines handle 12-17 sheets of...

Read More »Metso to Supply a Metal Recycling Plant to EMR in the USA

Published Jan 14, 2008 15:01 +2 GMT Kati Renvall Metso Minerals will supply a complete metal recycling plant to European Metal Recycling (EMR) for its recycling facility in Minneapolis, Minnesota, in the USA. The delivery will be completed during the first quarter of 2009. The value of the order is approximately EUR 8 million and it was included in Metso's fourth quarter order backlog of 2007....

Read More »

Industry Leading OEM with over 65 Years of Experience

Blonder Tongue Laboratories provides ISO 9001:2015 certified electronic contract manufacturing services at our on-site lab. We specialize in video distribution, fiber optics, and communications but have a variety of services available to bring your products to market. See our video to learn more.

Read More »