Fiber is designed for use in firefighter turnout gear.

Engineered to react and expand when temperatures reach 250Ã-

Read More »Engineering Thermoplastic Material is chemically resistant.

ULTEM can is designed for direct digital manufacturing applications. High temperature, high-performance engineering thermoplastic material can be used across industries for nearly any digital manufacturing project, from functional prototypes to jigs & fixtures to low volume production runs.

Read More »

High-Temperature Materials benefit bearing applications.

Metcar Grade 2500 and Metcar Grade 9800, which exhibit oxidation resistance without sacrificing self-lubricating properties, can be used in manufacturing non-galling and dimensionally stable bearings and thrust washers to promote extended product life. While Metcar Grade 2500 is suited for general-purpose applications with operating temperatures from 700 to 1,000Ã-

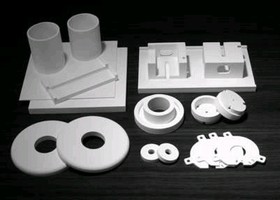

Read More »Refractory Sheet Board contains no asbestos or RCF fibers.

Consisting of reinforcing fibers tightly bound in alumina ceramic matrix, RS-1200 provides thermo-mechanical and electrical insulation in applications with temperatures up to 2,372Ã-

Read More »

3 Formulation Methods to Reduce Lean Giveaway for Processed Meat

Download this white paper, and learn about three methods that can help you improve your bottom line and yield by reducing lean tissue giveaway.

Read More »

Refractory Sheet suits applications in excess of 1,650-

Consisting of medium-density, fiber-reinforced ceramic composite material with greater than 99% Alpha-Alumina purity, Type RS-99 is suited for Solid Oxide Fuel Cells and setters for P/M and MIM sintering applications. Fired density of 130 lb/ftÃ-³ allows it to be machined to tight tolerances with standard tooling. Type RS-99M is highly plastic moldable sheet. Type RS-99W can be moistened with...

Read More »

Refractory Sheet Board suits high-temperature applications.

Consisting of combination of strong reinforcing fibers tightly bound in alumina ceramic matrix, Type RS-1200 provides thermo-mechanical and electrical insulation in applications with temperatures up to 2,372Ã-

Read More »Refractory Castable offers alternative to 1:2:4 field mix.

Offering quality control from raw material specifications to manufacturing process, Kaolite 1:2:4 is tested by outside testing lab for standard quality conformance. Product, which can be gun or cast, is comprised of 1 part Lumnite or other mid-grade calcium aluminate cement; 2 parts haydite, expanded shale; and 4 parts vermiculite. Physical properties include 48-56 lb/ft-³ density and 400-500...

Read More »

Von Ruden's Driven Tools Are Built to Last

Von Ruden's driven tools are designed to each specific machine in order to maximize performance. All of our tools are performance tested and made in the USA per ISO 9001:2015 standards. Check out our video to learn more.

Read More »