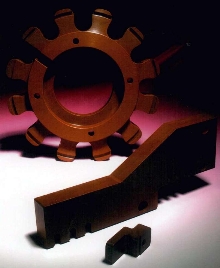

New Grades of Meldin-® Polyimide Materials

The Polymer Products Business of Saint-Gobain Performance Plastics has recently developed a grade of MeldinÃ-® materials for highly demanding applications in which metal and other materials will not perform adequately. Applications include thrust washers, sealing rings, bearings, and fork pads. The MeldinÃ-® 3100 series offers 4 tribological grades that satisfy application needs of high...

Read More »

Medin-® 7021 Polyimide Chosen for Performance

Saint-Gobain Performance Plastics' Meldin 7021 material has been selected for use in turbo prop engines. A major worldwide turbo prop manufacturer has tested, approved and purchased Meldin 7021 parts for valves that supply air to the aircraft cabin. The seal rings and bushings, made from Meldin 7021 compounded material, provide self lubricated bearing surfaces and resistance to high temperatures...

Read More »Heat-Resistant Material is used in glass making industry.

MeldinÃ-® 7001 polyimide parts and shapes offer heat resistance up to 600Ã-

Read More »

Polyimide Material is targeted for beverage industry.

Meldin 7001 polyimide material was developed for manufacturing cap holders for beverage packaging industry. Machined holders constructed from Meldin 7001 position plastic cap during hot welding process that connects cap to carton. With heat resistance up to 600Ã-

Read More »

Choosing an Optimal Riot PPE Supplier: 5 Key Factors

This ebook provides 5 key factors to choosing an optimal riot PPE supplier.

Read More »

Polyimide Parts meet outgassing and ionic purity standards.

Pyropel HD thermoset polyimide machining stock, suitable for manufacturing parts subject to high temperatures or chemical attack, offers temperature resistance to 550 deg F. It is available machined to print or in standard 12 x 12 in. plates in thicknesses up to 1 in. Applications include metal welding and cutting equipment; wafer processing equipment; soldering fixtures; high-pressure thermal...

Read More »

Ensure Your Medical Device Meets Regulatory Standards with Triad's Custom Magnetics

Triad Magnetics' custom components for medical devices are designed and manufactured with the strictest regulatory standards in mind. Our capabilities include rapid design, prototyping, and testing of inductors, transformers, and power supplies for medical equipment. Check out our video to learn more.

Read More »