Hand Knife features ergonomic design and sure grip.

Designed with rugged, soft-grip handle with no-slip texture, Quarter-Moon Hand Knife has blade made of 1095 high-carbon steel to hold edge longer than comparable knives made of lesser steels. Back edge of knife is not sharp to help prevent cuts and nicks to hand. Able to be re-sharpened for years of use, knife is suited for shaping linoleum floors, trimming excess PVC welds, cutting and skiving...

Read More »ArmorEdge(TM) Cuts the Competition! White Lightning(TM) Strikes Vegas!

VERONA, Va.Ã- — PersonnaÃ-®, the world's leading manufacturer of high-quality carpet blades and bladed tools, will feature new products at SURFACES in Las Vegas, NV, January 28-30, 2014. Featured products will include ArmorEdge™ Carpet Blades, which raise the bar for sharpness and durability, and the White Lightning™ Aluminum Fixed Blade Carpet Knife. Recognized as the leader in...

Read More »

Precision Loop Hoof Knife reduces stress on hands and wrists.

Ergonomically engineered for use by left- and right-handed workers, 6.5 in. long Hyde Loop Hoof Knife reduces stress, wear, and tear on wrists and fingers of farriers while effectively trimming frog and soles of hoofs. Blade utilizes .515 in. dia x 1.3 in. long, CNC-machine ground, high-carbon steel cutting edge that is sharpened on inside and mounted to HammerHeadÃ-® molded handle. Latter...

Read More »IRWIN Tools Reshapes the Utility Knife Category to Ensure Professional Tradesmen Have the Best Knives to 'Handle' the Job

HUNTERSVILLE, N.C., April 11, 2011 - IRWINÃ-® Tools, a world-class manufacturer and marketer of a broad line of professional hand tools and power tool accessories, introduces a complete line of ergonomic and durable utility knives and specialty knives to maximize tradesmen's productivity in extreme and ever-changing work environments. Each of IRWIN Tools' new knives -- the ProTouch(TM)...

Read More »

Wear - What Wears in Electromagnetic Brakes

Learn the common causes of wear for "fail-safe" brakes and how to prevent wear for safe use.

Read More »Go Green with Re-Sharpened Folder Knives from IGS Knives

IGS Knives, Inc., in Red Lion, PA wants to encourage customers to re-sharpen, don't keep buying new knives. Many folder knives are made in segments and the dull section is discarded. Use the IGS Knife-recycle, save money & stop the waste. IGS Knives last longer because they are made with durable Tool Steel and can be sharpened at one-half the price of a new knife. Return your IGS manufactured...

Read More »

Blades and Hand Knives cleanly cut tough, reinforced hose.

Made of M2 high-speed steel, Hose Hog(TM) Hose and Tube Cut-Off Blades slice materials such as wire-reinforced hydraulic hose in automated manufacturing operations with little to no post-cut cleanup. Hose Hog Hand Knives can hack, pry, cut, shear, trim, slit, or slice materials, including hydraulic hose. They are precision ground for max cutting leverage and reduced binding through cut. Line...

Read More »

Professional Grade Hose & Tube Blades Cut Through The Toughest Materials in the Plant and in the Field

Southbridge, MA - An extensive line of circular knives and blades and hand knives designed for cutting hose and tube materials in the production process or in aftermarket applications by professionals is available from Hyde Industrial Blade Solutions (IBS). Whether for the manufacturing plant or cutting hose and tube in the field, Hyde IBS Hose and Tube Blades move through the toughest materials...

Read More »Hand Utility Knives offer durable/comfortable design.

Featuring one-handed blade opening for easy activation, Fastback(TM) Utility Knife has tool-free blade change for efficient adjustments as well as gut hook and wire stripper which allow user to make cuts without exposing blade. Activated by side sliding mechanism, Sliding Utility Knife includes rubber overmold that maximizes comfort and helps avoid hand slippage. Unit also provides blade storage...

Read More »

Air Knife withstands corrosive environments.

With ability to withstand temperatures up to 800Ã-

Read More »

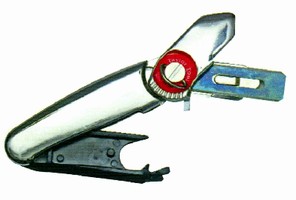

Carpet Knife offers quick blade changeouts.

Carpet Cricket Knife Model 503 offers one-handed Quick Flip blade change technology as well as gap-free tip, which completely supports blade, and high-traction swivel surface for smooth operation. Blade holder is made of tough plastic to protect edges of stored blades and also features textured grip and cut-out to facilitate blade removal.

Read More »

SRG Global Coatings Enhance Surface Durability, Efficiency, Design Flexibility

SRG Global's automotive coatings enhance the structural integrity of the finished part while also improving vehicle efficiency. Check out our video to learn more.

Read More »