CVT Belt utilizes carbon tensile cord.

Engineered for drop-in performance, G-Force™ C12 Continuously Variable Transmission Belt is designed for ATVs, UTVs, and snowmobiles. Cords are bonded to specially formulated adhesion gum with aramid fiber loaded rubber, which results in side-load resistance, preventing belt distortion and edge cord pullout. Belt also uses neoprene, which features trapezoidal top-notch and rounded bottom cog...

Read More »

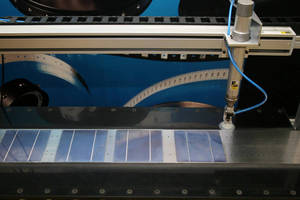

Stainless Steel Vacuum Belts for Solar Cell Production

High Performance Vacuum Belts Improve Efficiency and Throughput Agawam, MA - Belt Technologies offers a line of high performance stainless steel vacuum belts for use in the production of solar cells. Belt Technologies vacuum belts offer significant advantages over other conveying systems including high strength-to-weight ratio, durability, and precise positioning control. They run without...

Read More »

Conveyor Belt is designed for food processing applications.

Accepted by USDA NSF/ANSI/3-A hygiene standards, CompactGridÃ-® is hygienically designed to protect food processing products from contamination by deadly pathogens such as salmonella. Made of stainless steel with 70% open area, conveyor belt is designed to replace balanced weave belts and hard to clean plastic modular belts.

Read More »

Shrink Tunnel Belt features 1.1 in. pitch.

Designed for packaging industry, uni OWL belt features radius top design with nonstick surface that facilitates plastic film release and minimizes product contact for optimal and accelerated heating/cooling. Its 65% open design is suitable for applications with operating temperatures up to 356Ã-

Read More »

Automation Streamlines Medical Kit Assembly

Automation technology is key to streamlining medical kit assembly operations. Our eBook delves into the benefits of automation, the industries it serves, and its role in COVID-19 response.

Read More »Batson Expands Belting Line

Greenville, SC: Louis P. Batson Company recently announced the expansion of their belting line! Standard fabrications are available including: rubber, nitrate, butyl and PVC cleats, splicing, lacing, flanges, V-guides, edge finishes, hole punching and grooving. However, design services for special fabrications can be arranged. Belting includes: Flat Belts: o Flat traction drive power applications...

Read More »

Cooling Belt suits conveyors in food applications.

Developed for cooling conveyors in bakeries and other food applications, uni M-TTB CS, 0.5 in. pitch plastic modular belt features rounded bottom surface, making it suited for use with high-speed tight transfer conveyors. Belt features top curved surface and incorporates POM-D material with self-lubricating component that minimizes friction and optimizes nonstick characteristics. Cleaning is...

Read More »Radius Belts are offered as spiral/side flexing solutions.

Designed around pin/rod technology that lends to belt strength, uni Flex ASB (1 in. pitch) and uni Flex L-ASB (2 in. pitch) are available with or without hold down tabs in combination with flat or curved surface. Beam strength is also optimized for spiral and other side flexing applications.

Read More »Plastic Modular Belt has 2 in. pitch and SS reinforcement.

Able to replace stainless steel wire mesh belts used in blanching, cooking, and steaming applications, uni BLB design combines plastic with stainless steel (SS). This ensures conveyed products, such as fragile fruits, vegetables, rice, and pasta, are only in contact with plastic while also ensuring belt has strength and high-temperature resistance of steel.

Read More »

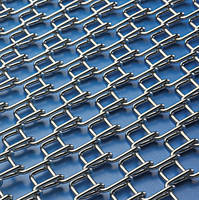

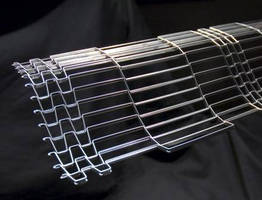

Cambridge International, Inc. Attends International Poultry Show in Atlanta, GA

Cambridge, MD, January 28, 2009 - Cambridge International, the world's largest manufacturer of metal conveyor belting, announces its participation the International Poultry Exposition. The event will take place from January 28-30, 2009 in Atlanta, GA. Every segment of the poultry and egg industry will be represented: feed milling, live production, hatchery, processing, further processing,...

Read More »Silicone Coated Food Belts Press Release

2/11/08 Habasit America introduces three new high duty, food grade, silicone coated conveyor belts: WVT-143, WVT-138, and WVT-140. These belts were designed with a high-quality food grade silicone coating providing excellent abrasion resistance, release properties and long life. Made especially for sticky food applications including: breakfast bars, candy, gum, pastries and protein bars. Habasit...

Read More »

ISO-Certified Plastic Injection Molding from Rodon

The Rodon Group is a proven leader in high-volume, close tolerance injection molding. We offer globally competitive, innovative manufacturing solutions for a broad range of industries. Check out our video to learn more.

Read More »