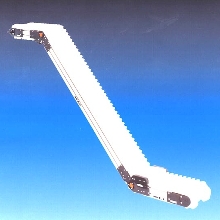

Conveyors offer 1 or 2 adjustable pivot points.

LPZ Series provides load capacity up to 1,000 lbs and maximum conveyor speed of 600 fpm. Conveyors are available in widths from 6 to 48 in. in 2 in. increments, and come in any distance in 1/8 in. increments. They include sealed bearings, T-slots for mounting of accessories, and optional V-guided belts for no tracking adjustments. Applications include packaging, plastic molding, metal forming,...

Read More »Conveyor eliminates belt drift.

Modular, aluminum-frame PowerTrac(TM), with V-guide belt tracks, keeps belts centered. Low-profile PowerTrac model is 1.875 in. high with widths from 2 to 24 in. and lengths to 20 ft. Medium-Frame PowerTrac Conveyor measures 3.875 in. high, with widths from 4 to 36 in., and lengths to 100 ft. Conveyor offers sealed, self-aligning bearings and knurled, stainless-steel rollers. Magnetic models are...

Read More »

Bearing Solutions For Your Robotics and Automation Applications

This ebook provides an in-depth overview into bearing solutions for your robotics and automation applications.

Read More »

Precision Fabricating with Over 40 Years of Experience

Quality Sheet Metal specializes in delivering precision, value, and customer service. With a client base that spans many diverse industries and a reputation for excellence that goes back over four decades, our clients know that we can provide the optimal combination of value and flexibility regardless of the challenge. See our video to learn what we can do for you. Through investments in state-of-the-art design, manufacturing, and quality control systems, Quality Sheet Metal remains focused on maintaining a high standard of quality, customer service, and competitive pricing. With an emphasis on customer satisfaction, Quality Sheet Metal is dedicated to establishing long-term partnerships, similar to the ones they currently have with their valued clients. If you're looking for a new partner with extensive capabilities in sheet metal fabricating and finishing, look no further.

Read More »