When Varying Sanitation Levels Make Sense While Improving Your Bottom Line

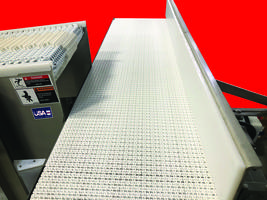

Multi-Conveyor (Winneconne, WI) - Multi-Conveyor recently built a food-grade transport conveyor system consisting of two levels of sanitary compliance. The initial conveyors are stainless steel constructed for maximum 3A Dairy compliance as required to move processed cheese in a food-grade, wash-down atmosphere through the bagging process. The filled bags then travel through a sectional wall, into a reduced sanitation area of the line where much more cost-effective, sanitation Level 2 conveyors made of painted mild steel are acceptable.

The design chosen also utilizes guideless conveyance to transport the bags. Only the contact with the belt delivers the bags to their next destination. A ninety-degree bag transfer and backstop are used to assist in the combining of two timed release lanes of product to a single lane and also to change bag orientation. The backstop helps guide the flexible package wide-edge leading from the transfer onto the transport sections and 90-degree curves to the case packer.

Another case packer is fed by a tabletop conveyor that conforms to the customer’s floor plan line layout. LBP transitions were strategically placed in conveyor-to-conveyor transfer sections. (Note: Products used in this video are for demonstration purposes only.)

The customer’s decision to use high-level sanitary ground and polished welded construction only where necessary; then, completing the line with painted mild steel constructed conveyors through metal detection, labeling, and into the case packing area, significantly reduced the project’s cost.

Learn the benefits of wash-down, sanitary stainless steel conveyor construction vs. painted mild steel systems. Evaluate the difference. Perhaps a combination of the two is right for one of your future production lines.

Then, call us at +1-800-236-7960. We look forward to designing your next conveyor system. Remember, Multi-Conveyor. your best conveyed better.

About Multi-Conveyor

Multi-Conveyor is a leading manufacturer of both pre-engineered standard and uniquely designed custom conveyor solutions for CPGs, End-Users, Integrators, Engineering firms, Automation/Robotics, AI, OEM, and Contract Packagers across multiple markets. Our products are multiple and unique. No single conveyor product defines a Multi-Conveyor. We specialize in conveyor systems for packaging or material handling for nearly every industry, product, shape, and size. Our customers report they select Multi-Conveyor for concept/design, engineering skills, quality product, best value, and prompt delivery.

Watch this equipment in action: https://youtu.be/MPefhb5bWLU

Contact Info for Publication:

Multi-Conveyor LLC

P O Box 10

Winneconne, WI 54986

+1-800-236-7960

info@multi-conv.com

www.multi-conveyor.com

PR Contact Non-Publication:

cmiller@multi-conv.com