Selective Soldering Machines work with lead-free alloys.

Press Release Summary:

Model 300L and 400L are suited for selective soldering of conventional (through-hole) components after reflow process. First machine can utilize pre-heater and includes bare board or mask grippers, internal spray or drop jet fluxers, and various soldering nozzles from 4-30 mm dia. Building on features of 300L, 400L offers 3-stage inline system for automated soldering process. It can also be customized to meet specific requirements.

Original Press Release:

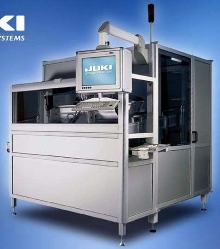

Juki Enhances Product Line With New Selective Soldering Equipment

New machines offer superior value and soldering flexibility, as well as lead-free capabilities...

MORRISVILLE, N.C. - (May 9, 2005) -To meet the demands of a rapidly changing industry, Juki Automation Systems has introduced two new selective soldering machines - the 300L and 400L. Incorporating more than 17 years of experience in the surface mount industry, Juki's new machines offer the same lowest lifetime cost of ownership as all other Juki systems. These machines are compatible for use with lead-free alloys.

"As the amount of through-hole components continues to decrease, there is a growing requirement for more flexible soldering systems," said Bob Black, Chairman and President of Juki Automation Systems. "Wave soldering is too slow and too dedicated for today's products. Our new selective soldering equipment not only fills this market need, but does so with the promise of Juki quality, durability and flexibility."

The Juki 300L is the economical solution for selective soldering of (through-hole) conventional components after the reflow process. and includes bare board or mask grippers, internal spray or drop jet fluxers, and installation of various soldering nozzles ranging from 4mm to 30mm in diameter. It offers a drop jet for smaller soldering areas, a spray fluxer for larger soldering areas, and has a pressurized tank that supplies flux consistently to the spray heads. The machine also utilizes a powerful pre-heater when it is necessary to solder a large quantity of components. For special applications, product-specific masks can be used for solder heated components while protecting neighboring components that may be heat sensitive.

The Juki 400L is a high-end selective soldering system, optimal for selective soldering of conventional components after the reflow process. In addition to all of the functionality of the Juki 300L, the Juki 400L also offers a three-stage inline system for a high-speed, automated soldering process. The Juki 400L can also be customized to meet specific requirements, such as configurations with three miniwaves in a panel, two miniwaves in a panel with different nozzles, or with one miniwave plus one full wave system. The 400L also offers many options to further enhance and customize the system to meet various requirements.

About Juki Automation Systems

Juki Automation Systems Inc., the U.S. division of Tokyo-based Juki Corporation's Electronic Assembly and Test Systems Division, is a leading supplier of SMT automated assembly equipment to the printed circuit board assembly market. Since 1987, Juki has shipped more than 10,000 SMT systems, making it one of the world's largest suppliers of SMT Assembly equipment.

For more information on Juki, contact Juki Automation Systems by phone at 919-460-0111, by fax at 919-469-0480, by mail at 507 Airport Blvd., Morrisville, N.C. 27560, or at www.jas-smt.com on the Web.