Rotary Lobe / Circumferential Pumps

Rotary Lobe Pump is designed for difficult applications.

Press Release Summary:

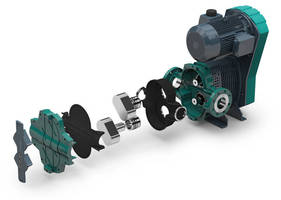

Along with 2 hardened steel lobes that rotate in geometrically adapted elastomer insert, TORNADO® T2 self-priming, valve-less, positive displacement pump features pulsation reduction system and synchronous toothed belt drive system. Elastomer insert design conserves energy, reduces wear, and increases service life, while FSIP™ design fosters access for inspection/service. Pump handles any kind of liquid and can be used in intermittent, continuous, or metering applications.

Original Press Release:

NETZSCH Announces Revolutionary TORNADO® T2 Rotary Lobe Pump

Redesigned to increase reliability, maintenance and performance, while reducing total cost of ownership

NETZSCH Pumps North America, LLC, experts in solutions designed specifically for difficult pumping applications, announces its innovative newly redesigned TORNADO® T2 rotary lobe pump. Self-priming and valve-less, the new TORNADO® T2 is a positive displacement pump ideal for any kind of liquid, including media containing gas, solids or fibrous matter. Completely redesigned to increase reliability, maintenance, and performance, while reducing the total cost of ownership, the TORNADO T2 pump can be used in intermittent, continuous or metering applications.

Unlike conventional rotary lobe pumps that use standard elastomer lobes, the redesigned TORNADO T2 uses two hardened steel lobes that rotate in a geometrically adapted elastomer insert. This bi-lobe rotor design creates a considerably longer housing sealing line, providing more wear padding. A specially developed pulsation reduction system ensures minimal pulsation or shear forces.

The new pump features an elastomer insert design that saves energy, reduces wear, and increases overall service life. Vulcanized onto the edges of the lobes to create a permanent hard-soft contact between the lobes throughout the 360° rotation cycle, the insert avoids high-wear contact between elastomer parts. The insert acts as a stator and is subject to less dynamic load and deformation than a traditional rotary lobe pump design.

The new pump design also replaces complex timing gear with a robust synchronous toothed belt drive system. The drive greatly reduces the danger of transmission damage and also decreases required weight and installation space. Since the drive requires no lubrication, the chance of oil leaks is completely eliminated.

The TORNADO T2 features the innovative FSIP™ (full service in place) design, which improves access for inspection, cleaning, service, and replacing parts. Simply removing the cover plate on the TORNADO T2 allows quick and easy access to the pump chamber. The rotors can be removed and replaced easily and quickly because they are not bolted or keyed to the shafts inside the pump head. The rotors’ geometry allows their independent removal without the need for special tools.

For more information contact:

Kristin Nugent

McNeil, Gray & Rice Inc.

(617) 367-0100, ext.148

Kristin.nugent@mgr1.com

About NETZSCH Pumps & Systems

NETZSCH Pumps & Systems has served markets worldwide for more than 60 years, providing customized, sophisticated solutions for applications in every industry type. Experts in solutions designed specifically for difficult pumping applications, NETZSCH supplies NEMO® progressive cavity pumps, TORNADO® rotary lobe pumps, and NOTOS™ multi screw pumps, as well as grinding machines, barrel emptying units, dosing technology and accessories. With a workforce of more than 2,000, NETZSCH Pumps & Systems is the largest business unit in the NETZSCH Group, with annual sales of more than 250 million Euros during the 2015 fiscal year.