NUMtransferCNC System Increases Efficiency and Profitability with Flexible and User-Friendly Transfer Machine Control

Exhibiting at IMTS in Chicago, Sept. 6 to 13, Booth D-3232

Chicago, September 11, 2006--In contrast with machining centers, rotary and linear transfer machines are comprised of multiple stations, which perform a multitude of operations on a work piece. The work piece is partially machined at each station, the sum of which results in a finished part. The increasing demand for smaller and flexible batches, greater variety of parts and faster or just in time delivery, requires improvement in transfer machines changeover and setup. Profitable use of these machines requires a system such as NUMtransferCNC, a flexible, efficient, and intuitive control system that is easy to navigate.

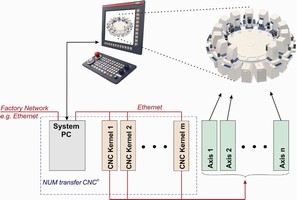

The stations of a transfer machines perform many different tasks. There are stations for turning, drilling, milling, grinding, and measuring, among others. The control system must be capable of easily incorporating the different stations into a seamless configuration. This calls for a control system architecture and operator interface that is customized for transfer machine applications. Instead of having to use abstract CNC-specific terms, such as names of axes and channel numbers, the operator should be able to work using familiar machine-specific terms and labels, such as station names.

Flexible control concept

The flexibility of the NUMtransferCNC system makes it adaptable to most transfer machine configurations. The basic system controls a maximum of eight stations and 32 axes. As many as nine axes can be interpolated within a single station. For larger machines, the system can be expanded, incrementally, to more than 40 stations and more than 120 axes. Machining operations, such as turning, milling, drilling, grinding, washing, and measuring can be intermixed arbitrarily to satisfy specific manufacturing requirements.

Flexible and user-friendly machine/process operating concept

The user-friendly interface of the NUMtransferCNC system allows the operator to use machine-specific operations and names. The names of the stations can be freely assigned and quickly identified. For very large machines, the stations can be combined into "modules," which can likewise be assigned a name. Every station and every module can be directly selected in any operating mode. The operator selects the corresponding functions without having to be concerned with which CNC channel executes these functions. This ability simplifies significantly the operator tasks, increases operating speed and reduces procedural errors.

The part program can be uniquely identified and labeled as they are created. The assignment of part programs and additional CNC data to the individual stations and modules occurs automatically. For larger transfer machines, it is quite common to reach a considerable number of tool offsets. The tools offsets can be assigned to the individual stations, greatly simplifying administration and execution. Moreover, the operator can choose whether to view all offsets or only those assigned to the currently selected station.

Simplification of debugging and troubleshooting

With such complex machines, reduction of down time plays a significant role and it is especially important that error messages are comprehensive and precise. The NUMtransferCNC system informs the operator of errors and if feasible, continues to operate. The error messages provide among other information details as to the module and station where the error initiated. It eases the service personnel task of searching and tracking malfunctions and errors. The error messages are saved to an alarm history file for later evaluation.

Machine-specific adaptations

In order to fully capitalize on the strengths of each transfer machine, the NUMtransferCNC system allows for customization of its standard configurations. Adaptations in the user interface and configuration are among the areas of possible customization. The NUMtransferCNC system gives you almost unlimited possibilities in achieving your goal of optimal and cost-effective machine operation.

This system will be presented at the IMTS trade show at McCormick Place in Chicago from Sept. 6 to 13 at the NUM Corporation booth, D-3232.

For further information, please contact:

NUM CORPORATION

Brian Kordzinski

Tel: 630-505-7722

Fax: 630-505-7754

E-mail: brian.kordzinski@num.com

Web: www.num.com

FRENCH TECHNOLOGY PRESS OFFICE

Contact: Kimberly Elsham

205 North Michigan Avenue, Suite 3740

Chicago, IL 60601

Tel: 312-327-5260

Fax: 312-327-5261

E-mail: contact.ftpo@ubifrance.fr