NUM CNC Solutions

Suite 115

Naperville, IL 60563-1452

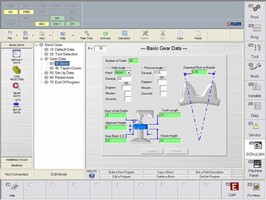

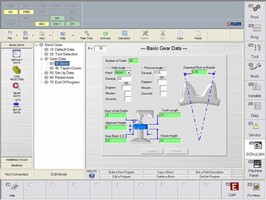

Gear Manufacturing for New Machines or Retrofits Made Easy with Num's Graphical and Conversational Software Solutions

Exhibiting at IMTS in Chicago, Sept. 6 to 13, Booth D-3232 Chicago, September 11, 2006--NUM offers a family of cost-effective control systems well suited to address all aspects of gear manufacturing. Configured with a state of the art CNC, motors/drives and very user-friendly software, these off the shelf solutions, can be used in new machines or to re-control existing machines. The embedded...

Read More »

NUM's Solutions for Grinding Have User-Friendly Graphical and Conversational Programming

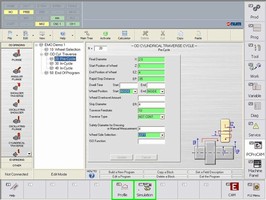

Exhibiting at IMTS 2006 in Chicago, Sept. 6 to 13, Booth D-3232 Chicago, September 11, 2006 NUM offers a family of cost-effective control systems well suited to address all aspects of cylindrical and surface grinding. Configured with a state-of-the-art CNC, motors/drives, and very user-friendly software, these off the shelf solutions can be used in new machines or to retrofit existing machines....

Read More »

NUM's CNC System Makes Programming Spin Forming a Breeze

Exhibiting at IMTS in Chicago, Sept. 6 to 13, Booth D-3232 Chicago, September 12, 2006 NUM's Axium Power CNC system combines a compact CNC with powerful on-board programming tools for spin-forming processes. The embedded spinning functionality, together with guided pre-form and spin-cycle setup routines, is combined with a graphical and user-friendly interface, known as the HMI, to provide a...

Read More »

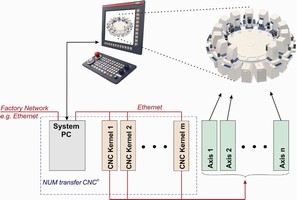

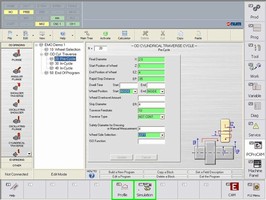

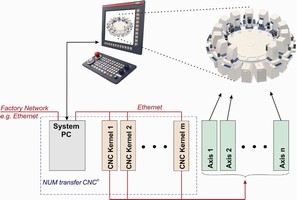

NUMtransferCNC System Increases Efficiency and Profitability with Flexible and User-Friendly Transfer Machine Control

Exhibiting at IMTS in Chicago, Sept. 6 to 13, Booth D-3232 Chicago, September 11, 2006--In contrast with machining centers, rotary and linear transfer machines are comprised of multiple stations, which perform a multitude of operations on a work piece. The work piece is partially machined at each station, the sum of which results in a finished part. The increasing demand for smaller and flexible...

Read More »

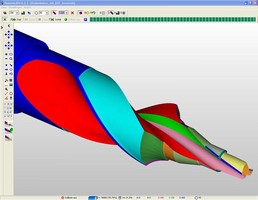

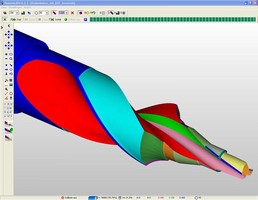

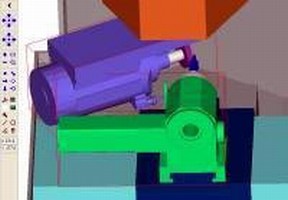

Collision Monitoring and 3-D Tool Simulation with Numrotoplus

Exhibiting at IMTS in Chicago, Sept. 6 to 13, Booth D-3232 Chicago, September 12, 2006 With the integration in the NUMROTO tool-sharpening programming software of three-dimensional tool simulation with grinding process animation and collision monitoring, a comprehensive total solution has emerged offering a wide range of functions and high operating convenience. The 3-D tool simulation for...

Read More »

Collision Monitoring and 3-D Tool Simulation with NUMROTOplus

Exhibiting at IMTS in Chicago, Sept. 6 to 13, Booth D-3232 Chicago, August 14, 2006 With the integration in the NUMROTO tool-sharpening programming software of three-dimensional tool simulation with grinding process animation and collision monitoring, a comprehensive total solution has emerged offering a wide range of functions and high operating convenience. The 3-D tool simulation for...

Read More »

NUM'S CNC System Makes Programming Spin Forming a Breeze

Exhibiting at IMTS in Chicago, Sept. 6 to 13, Booth D-3232 Chicago, August 2, 2006 NUM's Axium Power CNC system combines a compact CNC with powerful on-board programming tools for spin-forming processes. The embedded spinning functionality, together with guided pre-form and spin-cycle setup routines, is combined with a graphical and user-friendly interface, known as the HMI, to provide a highly...

Read More »NUM's Solutions for Grinding Have User-Friendly Graphical and Conversational Programming (W082)

Exhibiting at IMTS 2006 in Chicago, Sept. 6 to 13, Booth D-3232 Chicago, July 31, 2006 NUM offers a family of cost-effective control systems well suited to address all aspects of cylindrical and surface grinding. Configured with a state-of-the-art CNC, motors/drives, and very user-friendly software, these off the shelf solutions can be used in new machines or to retrofit existing machines. The...

Read More »

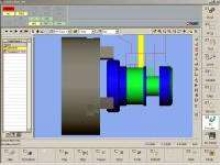

CNC Grinder uses graphical and conversational programming.

Axium Power CNC system addresses all aspects of cylindrical and surface grinding process. Embedded grinding/dressing cycles are governed by menu-driven data entry as well as wizard-guided wheel and diamond origin setup. Cylindrical grinding process allows for full OD/ID grind cycle for 2-axis grinding machines and provides inclined axis capability by tilting grinding head or table. For surface...

Read More »RTCP Function is suitable for 5-axis machining.

RTCP (Rotation Tool Center Point) Function maintains rotary axes at constant angle between tool and surface to be machined. Machine also allows OEMs to set up function based on mechanical properties of users' machines. RTCP function manages all irregularly shaped offsets automatically, and keeps tool in contact with programmed point. It uses contact point as reference point in all calculations,...

Read More »NUM Collaborates with Chinese Machine Builder to Develop Advanced 8-Axis CNC Multi-Function Machining Center

performs precision high speed laser cutting and milling with single clamping operation Naperville, IL, July 2, 2018 — CNC specialist NUM has helped the Chinese machine building company Original Point Machine Tools (OPMT) to develop an advanced 8-axis CNC machining center capable of processing many different types of materials, including metal, ceramics, glass and cemented carbide. OPMT is a...

Read More »

Gear Manufacturing for New Machines or Retrofits Made Easy with Num's Graphical and Conversational Software Solutions

Exhibiting at IMTS in Chicago, Sept. 6 to 13, Booth D-3232 Chicago, September 11, 2006--NUM offers a family of cost-effective control systems well suited to address all aspects of gear manufacturing. Configured with a state of the art CNC, motors/drives and very user-friendly software, these off the shelf solutions, can be used in new machines or to re-control existing machines. The embedded...

Read More »

NUM's Solutions for Grinding Have User-Friendly Graphical and Conversational Programming

Exhibiting at IMTS 2006 in Chicago, Sept. 6 to 13, Booth D-3232 Chicago, September 11, 2006 NUM offers a family of cost-effective control systems well suited to address all aspects of cylindrical and surface grinding. Configured with a state-of-the-art CNC, motors/drives, and very user-friendly software, these off the shelf solutions can be used in new machines or to retrofit existing machines....

Read More »

NUM's CNC System Makes Programming Spin Forming a Breeze

Exhibiting at IMTS in Chicago, Sept. 6 to 13, Booth D-3232 Chicago, September 12, 2006 NUM's Axium Power CNC system combines a compact CNC with powerful on-board programming tools for spin-forming processes. The embedded spinning functionality, together with guided pre-form and spin-cycle setup routines, is combined with a graphical and user-friendly interface, known as the HMI, to provide a...

Read More »

NUMtransferCNC System Increases Efficiency and Profitability with Flexible and User-Friendly Transfer Machine Control

Exhibiting at IMTS in Chicago, Sept. 6 to 13, Booth D-3232 Chicago, September 11, 2006--In contrast with machining centers, rotary and linear transfer machines are comprised of multiple stations, which perform a multitude of operations on a work piece. The work piece is partially machined at each station, the sum of which results in a finished part. The increasing demand for smaller and flexible...

Read More »

Collision Monitoring and 3-D Tool Simulation with Numrotoplus

Exhibiting at IMTS in Chicago, Sept. 6 to 13, Booth D-3232 Chicago, September 12, 2006 With the integration in the NUMROTO tool-sharpening programming software of three-dimensional tool simulation with grinding process animation and collision monitoring, a comprehensive total solution has emerged offering a wide range of functions and high operating convenience. The 3-D tool simulation for...

Read More »

Collision Monitoring and 3-D Tool Simulation with NUMROTOplus

Exhibiting at IMTS in Chicago, Sept. 6 to 13, Booth D-3232 Chicago, August 14, 2006 With the integration in the NUMROTO tool-sharpening programming software of three-dimensional tool simulation with grinding process animation and collision monitoring, a comprehensive total solution has emerged offering a wide range of functions and high operating convenience. The 3-D tool simulation for...

Read More »

NUM'S CNC System Makes Programming Spin Forming a Breeze

Exhibiting at IMTS in Chicago, Sept. 6 to 13, Booth D-3232 Chicago, August 2, 2006 NUM's Axium Power CNC system combines a compact CNC with powerful on-board programming tools for spin-forming processes. The embedded spinning functionality, together with guided pre-form and spin-cycle setup routines, is combined with a graphical and user-friendly interface, known as the HMI, to provide a highly...

Read More »NUM's Solutions for Grinding Have User-Friendly Graphical and Conversational Programming (W082)

Exhibiting at IMTS 2006 in Chicago, Sept. 6 to 13, Booth D-3232 Chicago, July 31, 2006 NUM offers a family of cost-effective control systems well suited to address all aspects of cylindrical and surface grinding. Configured with a state-of-the-art CNC, motors/drives, and very user-friendly software, these off the shelf solutions can be used in new machines or to retrofit existing machines. The...

Read More »

CNC Grinder uses graphical and conversational programming.

Axium Power CNC system addresses all aspects of cylindrical and surface grinding process. Embedded grinding/dressing cycles are governed by menu-driven data entry as well as wizard-guided wheel and diamond origin setup. Cylindrical grinding process allows for full OD/ID grind cycle for 2-axis grinding machines and provides inclined axis capability by tilting grinding head or table. For surface...

Read More »