Membrane Biofouling Mitigation through Applying Electric Potential in the CF016 Cell

Membrane filtration is an effective way to remove pollutants and microorganisms from water and wastewater. However, membrane fouling lowers efficiency over time when considering rejection values and water flux. Fouling is typically biological or particulate; fouling rate is a function of the membrane pore size relative to the size of the foulants and also the interactions between the membrane and the foulants. Membrane surface charges and affinity for water directly affect membrane biofouling intensity. Applying electric charge to the membrane surface is one of the methods that has been recently trending for mitigating biofouling [1]. Use of an electroconductive nano-carbon-based membrane has also been reported for mitigating membrane fouling by integrating membrane filtration [2].

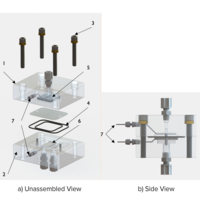

In an effort to meet the demand for a cross flow cell that allows users to apply alternating voltage to a flat sheet membrane, Sterlitech recently developed an Electrode Modified Cross Flow Assembly.

The CF016A Electrode Modified Crossflow Assembly consists of the following parts:

- Cell top

- Cell bottom

- Tightening screws

- O-rings

- Sintered metal support

- Titanium shim (0.083 inch thickness)

- Titanium electrods (1/16 inch diamter)

The CF016A Electrode Modified Crossflow Assembly is a laboratory-scale crossflow filtration unit that is designed to evaluate flat sheet membranes in a variety of applications. It simulates the flow dynamics of larger, commercially available membrane elements such as industrial spiral wound membrane elements.

Sterlitech Corp.

22027 70th Ave. S.

Kent WA 98032-1911

Phone: 253-437-0844

Contact:

Sales Department

email: sales@sterlitech.com