Latest EPIC Firmware 1.5.0 Software Supports CAN Bus Integration Module

Press Release Summary:

- Features visualization and external mass storage support

- Allows USB file access for PAC Control, CODESYS, Node-RED, and groov Manage,

- Offers upgrade to Node-RED 1.0.2, including editor, search, and core node enhancements

Original Press Release:

Opto 22’s groov EPIC Firmware 1.5.0 Adds New Visualization Features and External Mass Storage Support

New groov View gadgets and functions come to groov EPIC along with external HDMI touchscreen management and USB file access

Temecula, CA - December 19, 2019 – As the groov EPIC® platform passes the year-and-a-half mark in its maturity, appropriately enough, Opto 22 releases version 1.5.0 of its firmware. This release broadens the palette of visualization and storage options for groov EPIC to suit an even wider variety of applications and hardware.

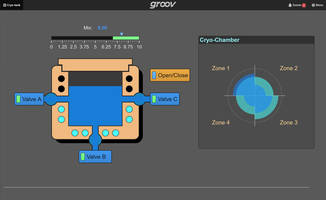

The embedded groov View server is updated to version 4.2, with functions to create even more dynamic web and mobile HMIs, dashboards, and Andon boards. New shape gadgets allow users to create custom SVG images and animations directly in groov View, and to dynamically change their color and size (height and/or width) based on process variables or on any other data source connected to groov EPIC. This version also introduces tag-driven conditional formatting for other gadgets, allowing users to make elements visible or invisible, as well as change text color and formatting.

These options could be used, for example, to enhance overhead displays for a bottling line by changing the color of text and numerical readouts to reflect line status or quality metrics stored locally in PAC Control™, CODESYS®, Node-RED, or Ignition®. For batch and continuous control applications, users could enhance situational awareness in operator interfaces by creating custom level and range indicators that change height and color in response to level, temperature, pressure, or alarm readings.

With groov EPIC 1.5.0, OEMs can also choose from a broader range of external HDMI monitors and touchscreens, including models from DELL, Hope Industrial, SuperLogics and AIS. This makes it even easier to eliminate Windows PCs and OITs for local viewing and operator interfacing, significantly reducing material and maintenance costs and total cost of ownership. groov EPIC 1.5.0 supports both resistive and capacitive models via its built-in HDMI port, and makes it possible to calibrate and configure them through groov Manage.

For engineers leveraging groov EPIC to implement distributed database, communication, and file servers, 1.5.0 now adds support for USB mass storage devices. This feature makes it possible to expand edge device servers beyond groov EPIC’s 6GB of SSD user space, further reducing the need for high-maintenance, general-purpose PCs in critical applications.

This update also adds USB file access for PAC Control, CODESYS, Node-RED, and groov Manage, allowing engineers to programmatically manage files, like uploading recipe configurations from a thumb drive to a control application running on groov EPIC, or creating a rolling buffer that automatically archives old data logs to attached storage.

groov EPIC has two USB ports that can support multiple drives, hubs, or serial adapters, as well as a single Netis USB WiFi adapter.

Other enhancements in this upgrade include

- Support for the new CAN bus integration module, GRV-CCANI-2.

- Upgrade to Node-RED 1.0.2, including editor, search, and core node enhancements, as well as under-the-hood changes for better debugging and more predictable flow logic.

Version 1.5.0 is a free upgrade for all groov EPIC users. Current customers can log into manage.groov.com and simply download the file and update their EPICs. Complete upgrade instructions are available in the groov EPIC User’s Guide. For new customers, all groov EPICs now ship with this latest firmware version.

About Opto 22

Opto 22 designs and manufactures industrial control products and Internet of Things platforms that bridge the gap between information technology (IT) and operations technology (OT). Based on a core design philosophy of leveraging open, standards-based technology, Opto 22 products are deployed worldwide in industrial automation, process control, building automation, industrial refrigeration, remote monitoring, and data acquisition applications. Designed and manufactured in the U.S.A., Opto 22 products have a worldwide reputation for ease-of-use, innovation, quality, and reliability. For over 40 years OEMs, machine builders, automation end-users, and nformationtechnology and operations personnel have and continue to trust Opto 22 to deliver high-quality products with superior reliability. The company was founded in 1974 and is privately held in Temecula, California, U.S.A. Opto 22 products are available through a global network of distributors and system integrators. For more information, contact Opto 22 headquarters at +1-951-695-3000 or visit www.opto22.com. Follow us on Instagram, Twitter, Facebook, LinkedIn, YouTube.

Contact:

Janice Colmer, Marketing Specialist

800-321-6786

jcolmer@opto22.com