JTAG Technologies Targets Functional Testers at Autotest 2014, St. Louis, Booth 727

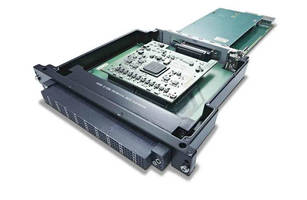

JTAG Technologies, leading supplier of Boundary-Scan Solutions, is showcasing amongst other products the new JTAG/boundary-scan hardware interface product compatible with the Virginia Panel (VPC) mass interconnect system. The JT 2147/VPC is a signal conditional module that allows 'ideal world' connections from JTAG Technologies PXI and PXIe DataBlasters to the VPC connection system.

Based on the highly successful QuadPod™ architecture from JTAG Technologies, the JT 2147/VPC has been specifically designed for connection into G20x or G14x 192 pin 'QuadraPaddle' connectors and is compatible with the VPC 'pull thru' system. By integrating the JT 2147/VPC, test system builders will greatly simplify their wiring task and, at the same time, retain the excellent signal integrity assured by the QuadPod's active interface.

The JT2147/VPC features four independent JTAG Test Access Ports (TAPs) along with 16 static DIO channels and 64 dynamic DIOS channels. Each TAP can be programmed to operate through a range of voltage levels to suit various logic families.

Peter van den Eijnden, MD comments on this new product: 'JTAG Technologies equipment is used world-wide within Mil/Aero and other industries as a component within functional testers. The JT 2147/VPC will greatly simplify the system builder's tasks and enhance the power of their test systems through improved signal conditioning.'

JTAG/boundary-scan applications prepared using JTAG Technologies ProVision or 'Classic' software tools may be executed on this PXI platform with driver packages that are available for NI LabView, TestStand and LabWindows alongside Geotest ATEasy and a number of generic language compilers (e.g. .NET framework, C++ and VB) . The VPC adapters utilize standard QuadraPaddle connector modules, providing a wide variety of contact types. The connection between the PXI(e) instrument and receiver module is accomplished using either a passive printed circuit board, active signal condition module (as with the JT 2147/VPC) or flex circuit, with each providing optimum connectivity performance while reducing wiring cost.

AutoBuzz , the most exciting addition yet to JTAG's no-netlist-required range of JTAG/boundary-scan test and debug tools-

Autobuzz -- Favourite also in MIL/AERO Repair and Service Centres

AutoBuzz is an amazing tool that uses a unique 'seek and discover' feature to scan completely a compliant design and then perform comparative tests using JTAG/boundary-scan.

With only JTAG scan-chain information plus BSDL models of the JTAG/IEEE std 1149.1 compliant parts (available from manufacturers' web-sites), users of AutoBuzz will be able to connect to their designs via a number of compatible JTAG interface options. AutoBuzz can then be set to gather a complete 'connectivity map' of any board's boundary-scan to boundary-scan pin connections (where these can be direct or via 'transparent' devices such as series resistors).

AutoBuzz supports just two simple operating modes: Learn and Compare. With AutoBuzz in Learn mode a 'known good' sample PCB is initially scanned to establish a reference connectivity map. Suspected faulty boards can then be scanned by AutoBuzz in Compare mode, and a comparison is automatically made of their connectivity maps. Differences between the two maps are highlighted to indicate possible faults such as interconnect short-circuits, open-circuits or 'stuck-at' faults.

For added reliability and reproducibility a constraints section allows critical pins to be set at fixed drive values as 'guards'. Since the user requires no boundary-scan technical knowledge and with only a basic scan chain input needed it is ideal for repair centres. Supported interfaces currently include Altera's USB Blaster, Xilinx's parallel III/IV and USB interfaces, JTAG Technologies' JT 3705 / USB controller, JTAG Live dedicated USB controller and some FTDI based modules.

AutoBuzz joins the JTAG Live range which not only includes the aforementioned Buzz and BuzzPlus, but also the programmable cluster test modules Clip and Script. The latter is a powerful Python-based API that enables users to create sophisticated boundary-scan based device or device cluster tests in an easy-to-learn, open-source programming environment.

For more information pls see www.jtag.com

About JTAG Technologies

JTAG Technologies is a market leader and technology innovator of boundary#8208;scan software and hardware products and services. The company was the first to bring to the market such important advances as automated test generation, automated fault coverage analysis, automated flash and PLD programming via boundary#8208;scan, and visualized boundary-scan analysis. Its customers include world leaders in electronics design and manufacturing such as Ericsson, Flextronics, Honeywell, Medtronic, Motorola, Nokia, Philips, Raytheon, Rockwell-Collins, Samsung, and Sony. Its innovative boundary-scan products provide test preparation, test execution, test result analysis and in-system programming applications. With an installed base of over 7000 systems worldwide, JTAG Technologies serves the communications, medical electronics, avionics, defence, automotive, and consumer industries with offices throughout North America, Europe and Asia. JTAG Technologies headquarters are located in Eindhoven, The Netherlands.

JTAG and JTAG Technologies are registered trademarks of JTAG Technologies, Inc. All other brand names or product names mentioned are trademarks or registered trademarks of their respective holder(s). www.jtag.com

Follow us !

JTAG Technologies and JTAG Live are on Twitter, Facebook, Google+, LinkedIn and YouTube.

Follow us to keep up to date of all the latest news!

Press contact:

Renate Fritz

email: renate.fritz@onlinehome.de