Collision Monitoring and 3-D Tool Simulation with NUMROTOplus

Exhibiting at IMTS in Chicago, Sept. 6 to 13, Booth D-3232

Chicago, August 14, 2006

With the integration in the NUMROTO tool-sharpening programming software of three-dimensional tool simulation with grinding process animation and collision monitoring, a comprehensive total solution has emerged offering a wide range of functions and high operating convenience. The "3-D tool simulation" for NUMROTOplus, from NUM Corporation, simulates the actual grinding process and presents it in a 3-D display. This software has also proven itself in practical use with its speedy simulation calculation.

Even extremely complex and precision-manufactured tools can be simulated with absolute detail and accuracy. To ensure clear identification during operation, each machining step is presented in a different color. The zoom and pivoting functions allow precise viewing and assessment of even the smallest movements and procedures. The exactness of the simulation can be individually set and the 3-D model can be precisely measured.

The simulation shows the material removal and estimates the grinding disc load. This enables considerable optimization of rough grinding. The simulation can also be used with absolute precision in small tool production-even the minutest tools can be simulated and displayed with the highest precision. The ability to run the simulation forward as well as backward has proven especially useful with delicate processes and geometries.

For example, a complete step drill with double flutes can simulated in about 15 seconds. This includes the zoom function and the pivotable 3-D model, thus allowing the view to be modified as desired without any further calculation time.

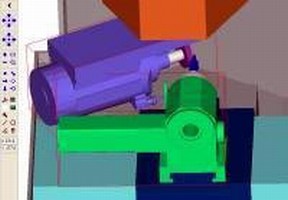

If the tool simulation is used together with the collision monitoring software, the machine model is likewise displayed during the animation of the grinding process.

The collision monitoring aspect of NUMROTOplus is a 3-D simulation that immediately recognizes kinematics problems based on the machine simulation. The calculation time required for, in this example, a step drill with profile steps and 13 machining steps amounts to less than three seconds. The exactness of the simulation can be individually set.

All the available elements in the 3-D machine model of the machine manufacturer are integrated in the collision evaluation. Additional machine-specific or processing-specific elements such as measuring probes, tailstocks, supports, spacer rings, cooling pipes, wheel flange nuts, and more can be added.

This software tests for possible collisions of any individual machine elements with each other, any grinding discs with the machine and machine elements, as well as any unengaged grinding discs with the blank. With this option, the grinding process can also be simulated without material removal. This function is very useful for monitoring the grinding position and cooling as well as for assessing the disc contact. It also simplifies, for example, the combining of grinding disc packages.

The collision monitoring in combination with the 3-D tool simulation offers a high-performance, practical, and flexible tool that can make the entire production process faster, safer, and more easily calculable.

NUMROTO is currently offered by 14 machine manufacturers in about 30 different machines-a strong argument for tool manufacturers and regrinding specialists, who could then use the same software for different machines. The comprehensive range of functions, which is continually adapted to changing demands, as well as the excellent support, are important cornerstones of success. This solution will be presented at the IMTS trade show at McCormick Place in Chicago from Sept. 6 to 13 at the NUM Corporation booth, D-3232.

For further information, please contact:

Brian Kordzinski

NUM CORPORATION

603 E. Diehl Rd., Ste. 115

Naperville, IL 60565

Tel: (630) 505-7722

Fax: (630) 505-7754

E-mail: brian.kordzinski@num.com

Web: www.num.com

or

FRENCH TECHNOLOGY PRESS OFFICE

205 North Michigan Avenue, Suite 3740

Chicago, IL 60601

Fax: (312) 327-5261

E-mail: contact.ftpo@ubifrance.fr