Stedman Machine Company

Aurora, IN 47001-0299

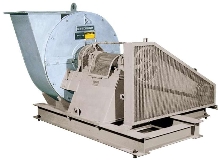

The Grand Slam(TM) Waste Recycler From Stedman

Aurora, IN - The Grand Slam(TM) Waste Recycler, manufactured by Stedman, is designed for sizing hundreds of materials and agglomerated wastes into carefully controlled uniform particle sizes, reducing maintenance time and expense. The Grand Slam Waste Recycler is capable of handling up to 100 tons of wet and sticky or dry and fibrous material per hour, and typical applications include: bakery...

Read More »Impactor reduces size of various materials.

Designed for size reduction of minerals, ores, and chemicals, V-Slam(TM) is equipped with indexing feed tube and anvil ring as well as automatic recirculating lubrication system. Hydraulic powered opening of top housing facilitates access, while overall design facilitates replacement of distributor plates, shoes, and other impeller components. Machine offers particle size reduction ratio up to...

Read More »

Cage Mill de-lumps and dries materials in one step.

Constructed with completely welded shell, cage mill with flash dryer handles temperatures up to 1200Ã-

Read More »

Crusher is suited for laboratory applications.

Designed for small production rates, Model GS1209 Lab Size Crusher is built for daily operation with wet and dry materials. Unit, with all welded steel construction and heat-treated plate in product contact areas, features rotor and breaker bars constructed of 4140 heat-treated steel. Available in stainless and carbon steel construction, crusher is controlled via adjustable primary and secondary...

Read More »

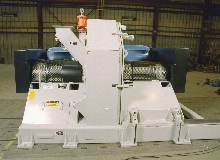

Cage Mill offers 2-4 or 6-row design.

Series H Multi-Cage Mill comes in 4 sizes up to 250 tph. Air cannons are mounted at intake and discharge to help prevent build-up of wet sticky material, while heaters are installed on grinder housing to retard buildup of wet material. Hydraulic ram eliminates gear head motor and rack and pinion used on other cage mills. Selective-crushing, controlled-impact mill sizes minerals, agglomerates,...

Read More »

Shim Kits help maintain gap settings on crushers.

Hydraulic Shim Kits include lift bridge weldments and hydraulic cylinders for both front and rear apron assemblies. Three-spool control valve actuates housing cylinders or apron cylinders. Counterbalance valves on both cylinders are provided for added safety should one hydraulic line fail. All necessary hoses and fittings are included.

Read More »Jim Suetholz Appointed as Central US Sales Manager

AURORA, IN - Jim Suetholz has been appointed as the central United States sales manager for Stedman Machine Company. Jim holds a Bachelor of Science degree in electrical engineering from the University of Kentucky. He has over 17 years of experience in capital equipment sales in the mining, steel and various other heavy industries throughout North America. Jim's responsibilities include selling...

Read More »Dan Egbert Appointed as Parts Sales Associate

Aurora, IN - Dan Egbert has been appointed as Stedman's new Parts Sales Associate. Egbert will be responsible for customer support of all crusher parts and spares. Egbert has over 19 years experience at Stedman, starting in the Shipping and Receiving Department. He also has experience in Unit Assembly and Installation and Service. His last position as Production Clerk has given him an extensive...

Read More »Stedman Appoints Eric Marcotte as New Southern U.S. Regional Sales Manager

Aurora, IN - Eric Marcotte has been appointed as the new Southern U.S. Regional Sales Manager for Stedman and Innovative Processing Solutions. Marcotte's responsibilities will include selling crushing equipment and systems to Stedman customers. He has over 3 years of experience in the mining industry, plant operations, and size reduction equipment. Marcotte received a Bachelor of Science in...

Read More »Open House in Honor of Stedman's 175th Anniversary

Aurora, IN - Stedman announces an open house on September 12, 2009 in celebration of its 175th anniversary this year. The open house is open to the public and local neighborhood, as well as to Stedman employees, retirees and family members. The mayor and town council of Aurora, Indiana, local senators, suppliers and customers are also invited to attend. Tours of the shop, office and test plant...

Read More »Victor Bentle Retires as Manager of Parts Department

AURORA, IN -- After 45 Ã-½ years of service, Vic Bentle is retiring. Officially, his retirement date is May 12, 2009; however, he will be on vacation from April 1 through May 12. Vic will be spending more time with his family and friends and in his workshop. He also enjoys traveling. Vic's career at Stedman started in 1963, when he was hired as a Draftsman. Shortly thereafter, he moved to the...

Read More »Doug Weber Promoted To Assistant Manager, Parts Department

Aurora, IN - Stedman announces the promotion of Doug Weber to Assistant Manager, Parts Department. Doug will be responsible for customer support for all crusher parts and spares, including breaker bars, bearings, electrical components and shafts. Before being named Assistant Manager, Doug began at Stedman in 1991 as a drafter in the engineering department. He then became a Parts Sales Associate...

Read More »Mike Browning Named Eastern Aggregate Sales Manager

Aurora, IN - Mike Browning has been named Aggregate Sales Manager for the Eastern Territory for Stedman Machine Company and Innovative Processing Solutions. Mike's responsibilities will include selling crushing equipment and systems to Stedman aggregate customers within the territory. Mike attended the University of Cincinnati and has over 14 years experience in equipment sales, representing...

Read More »Stedman Appoints Matt Uecker as New Industrial Regional Sales Manager

Aurora, IN - Matt Uecker has been appointed as the new Northern Territory Regional Sales Manager for Stedman Machine Company and Innovative Processing Solutions. Matt's responsibilities will include selling crushing equipment and systems to Stedman industrial customers. Matt received a Bachelor of Science in Mechanical Engineering from General Motors Institute in Flint, Michigan and has over 20...

Read More »Dennis Gilmour Promoted To Stedman President

Aurora, IN - Stedman announces the promotion of Dennis M. Gilmour to President. Mr. Gilmour has been with Stedman for nearly 30 years, starting with the company in 1978 as a sales engineer. Since his hire, Mr Gilmour has held such positions as District Sales Supervisor, Sales Manager, Vice President Sales & Marketing and Senior Vice President. Stedman Machine Company, in business since 1834, is a...

Read More »

The Grand Slam(TM) Waste Recycler From Stedman

Aurora, IN - The Grand Slam(TM) Waste Recycler, manufactured by Stedman, is designed for sizing hundreds of materials and agglomerated wastes into carefully controlled uniform particle sizes, reducing maintenance time and expense. The Grand Slam Waste Recycler is capable of handling up to 100 tons of wet and sticky or dry and fibrous material per hour, and typical applications include: bakery...

Read More »