The Witte Co., Inc.

P.O. Box 47

Washington, NJ 07882-0047

Fluid Bed Dryers Feature Independent Temperature Control Zones

Witte Co. Permits Multiple Heating Levels in Same Dryer, Protects Sensitive Products Washington, NJ: Vibrating fluid bed dryers from process equipment manufacturer. The Witte Co., Washington, New Jersey (www.witte.com), feature multiple temperature control zones that operate independently to permit a variety of different heating and cooling levels in the same continuous drying system. Ideal for...

Read More »

Fluid-Bed Dryers and Coolers prevent product blockages.

Dryers and coolers incorporate stainless steel decks that permit intimate product contact with drying air. Wedge-wire decks, with tapered slots measuring 1/100 in. on 1/8 in. centers, replace drilled-hole decks. Triangular-wire construction establishes immediate openings for airflow that prevent blinding and ease cleaning, while gentle airflow prevents product degradation, promotes product...

Read More »Automatic Weirs promote flush cleanout.

Autoweirs feature pneumatically operated radius gates that automatically rotate 60Ã-

Read More »Air Distribution System eliminates dead spaces.

Product offers CNC-punched air distributors placed below dryer deck to generate consistent, vertical air flow at constant velocity. Directing uniform air flow perpendicular to dryer deck throughout entire length of fluid bed, dual air distributors prevent formation of dead spaces that occur when air flow is angled or inconsistent. Unit's air distributors also eliminate conditions that cause...

Read More »

Drying System inhibits foods from sticking together.

Open access fluid bed drying system offers pre-drying zone that pre-treats sticky, extruded, and expanded products by removing outer layers of moisture that cause particles to stick together. Installed after dewaterer, pre-dryer permits smooth movement from Teflon-coated pre-dryer deck into vibrating fluid bed drying section. Pre-drying prevents blockages and reduces need for maintenance. Unit...

Read More »

Sanitary Clamp meets USDA, 3-A standards.

Sanitary Clamp permanently mounts on food and dairy processing, packaging, and material handling equipment to deliver up to 750 lbs of clamping force, yet retracts for instant access to machine or system. Made entirely of FDA-approved stainless steel or with aluminum frame, corrosion-resistant clamp is suitable for Clean In Place, Steam In Place, and manual washdown conditions. It features yoke...

Read More »Dewatering System drys, cools, and screens.

Model 400 integrated, multi-step system for pelletizing lines combines dewatering, drying, cooling, dedusting, and screening into single unit. It delivers product moisture levels at 0.04% in nylon applications and 0.10% in polyethylene, polystyrene, polypropylene, polyvinyl chloride, polyesters, polyurethanes and other commodity and engineering resins. Suitable for friable, glass-filled, and...

Read More »

Retractable Clamp allows easy removal of covers and doors.

Clamp permanently mounts to equipment, delivers up to 750 lb of clamping force, yet retracts with one hand to permit speedy removal and re-connection of covers, doors, panels, and hoods from machinery and equipment. It has stainless steel yoke and roll pin mounting assembly that permits clamp to be closed and opened without detaching it from equipment. Top-mounted handle seals and releases...

Read More »

Drying System eliminates exhaust to atmosphere.

Self-contained, closed-cycle, fluid bed-drying system dries solvent-based products, pesticides, and chemicals. Integral bag collector, atop of fluid bed dryer, permits processing of powders down to 10 microns, capturing 100% of entrained product and returning material for further processing and discharge. System cools exhaust air to condense and reclaim solvent and/or water for reuse, without...

Read More »

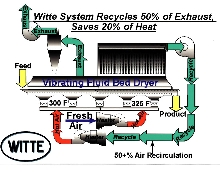

Fluid Bed Drying System recycles exhaust air.

Drying system recycles 75% of heated exhaust air through continuous pulse jet dust collector and reheats it in natural gas burner, during drying of rice, salt, limestone, sawdust, polymers, inorganic chemicals and other products that require temperatures of 150+ Ã-ºF. System permits process to operate at high outlet moisture while staying comfortably above dew point of final exhaust air.

Read More »Witte Company Celebrates 80th Anniversary

Milestone Marks Four Generations of Vibratory Process Equipment Innovation Washington, NJ: Process equipment manufacturer The Witte Co., Washington, New Jersey (www.witte.com), is celebrating its 80th anniversary as a pioneer in the development of vibratory fluid bed dryers, coolers, classifiers, screeners, and other machinery. Founded by Richard Witte in New York City in 1938 to meet demand for...

Read More »New Literature Showcases Line of Vibrating Process Equipment

Witte Co. Provides Detailed View of Fluid Bed Dryers, Classifiers, Auxiliary Equipment Washington, NJ: A new brochure from process equipment manufacturer The Witte Co., Washington, New Jersey (www.witte.com) showcases the company's line of vibrating fluid bed dryers, coolers, pellet classifiers, screeners, conveyors and other vibrating process equipment. Presenting the 4th generation,...

Read More »Process Equipment Manufacturer the Witte Co. Names Tyson Witte 4th Generation President

High Quality Manufacturing, Repeat Customers Remain Hallmarks Since 1938 Washington, NJ: Process equipment manufacturer The Witte Co., Washington, New Jersey (www.witte.com), has named Tyson Witte president. Promoted after 10 years of service in engineering and in other roles, Tyson represents the fourth generation of leadership for the family-owned manufacturer of vibrating fluid bed dryers,...

Read More »Witte.com Features In-Action Videos Gallery, Free, Educational PDFs, Case Studies

Washington, NJ –Ã- A new Web site from process equipment manufacturer The Witte Co., Washington, New Jersey at www.witte.com showcases the company's line of vibrating fluid bed dryers, coolers, pellet classifiers, screeners, conveyors and other vibrating process equipment. Featuring in-action videos, a sharp photo gallery, customer case studies, process flow diagrams and educational...

Read More »New Literature Showcases Plastic Pellet Classifiers

The Witte Co. Reveals Advances In Pellet Separation Science Washington, NJ: Process equipment manufacturer The Witte Co., Washington, New Jersey (www.witte.com), has unveiled new technical literature showcasing the company's vibrating plastic pellet classifiers. Entitled, 200 Series Plastic Pellet Classifiers , the literature describes how the classifiers efficiently separate and remove fines ,...

Read More »

Fluid Bed Dryers Feature Independent Temperature Control Zones

Witte Co. Permits Multiple Heating Levels in Same Dryer, Protects Sensitive Products Washington, NJ: Vibrating fluid bed dryers from process equipment manufacturer. The Witte Co., Washington, New Jersey (www.witte.com), feature multiple temperature control zones that operate independently to permit a variety of different heating and cooling levels in the same continuous drying system. Ideal for...

Read More »Blinded by the Price - Process Equipment Manufacturer Offers Guidance for Buying Used Equipment

Washington, NJ, USA: When scouring the Internet for equipment bargains, a lack of information makes it hard to be sure which ones are legitimate and which ones are lemons in disguise. Since many machines posted for sale online do not come with a warranty, user manual, maintenance log or chain of custody documenting prior owners, eager shoppers considering auctions and plant liquidation sales need...

Read More »Process Equipment Manufacturer Unveils Four-Point Spare Parts Service

Witte Stocks Parts, Ships Next Day, Machines New, Includes Preventative Maintenance Guide Washington, NJ: Process equipment manufacturer The Witte Co., Washington, New Jersey (witte.com), has unveiled a four-point spare parts service to provide companies with speedy access to the spare parts that most commonly require repair or replacement for reduced line downtime and minimal disruption for...

Read More »Process Equipment Manufacturer Documents Free Tests Online, on DVD, for Fast Global Review and Collaboration

New Service Records Tests On Full-Size Drying, Dewatering, Screening Equipment Washington, NJ: Process equipment manufacturer The Witte Co., Washington, New Jersey (www.witte.com), has introduced a free service recording tests conducted on its line of process equipment in live action, high-definition video. Posting the videos online, the new testing service permits immediate review by multiple...

Read More »

Fluid-Bed Dryers and Coolers prevent product blockages.

Dryers and coolers incorporate stainless steel decks that permit intimate product contact with drying air. Wedge-wire decks, with tapered slots measuring 1/100 in. on 1/8 in. centers, replace drilled-hole decks. Triangular-wire construction establishes immediate openings for airflow that prevent blinding and ease cleaning, while gentle airflow prevents product degradation, promotes product...

Read More »