Standard-Knapp, Inc.

Portland, CT 06480

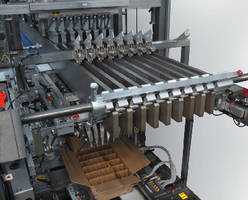

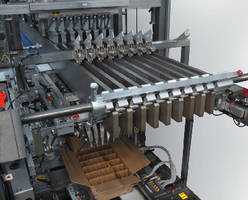

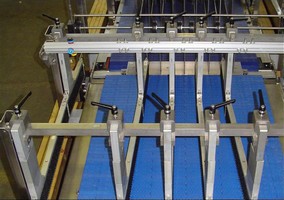

Case Packer offers flask handling option.

With thicker lane guides, Versatron™ Case Packer allows for safe and gentle packing of 100, 200, and 375 mL flasks. Also available, Pic-N-Place case filling module provides direct, automatic control of product and gentle placement without need for lift table, minimizing breakage and protecting labels.

Read More »

Continuous Motion Uncaser has 70 case/min capacity.

PikMore Uncaser features gripper heads that revolve around center carousel to lift empty glass bottles from their cases. Bottles are then placed on conveyor as they leave machine. Continuous motion machine includes graphic operator interface screen that enables mostly automatic operation. Programmed for auto lubrication, product also times all operations through trigger on main carousel, and is...

Read More »

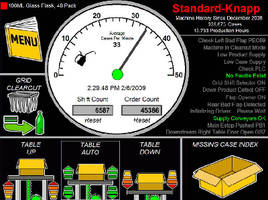

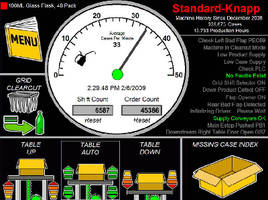

Machine Operator Interface integrates color touchscreen.

Able to be customized to each Standard-Knapp machine, smart Operator Interface is graphically driven and utilizes color touchscreen technology to offer intuitive machine control. Computer-aided fault recovery minimizes mean time to recover (MTR) and promotes efficiency for 24/7 applications in food and beverage industries. Along with color-coded alerts, features include machine history display,...

Read More »

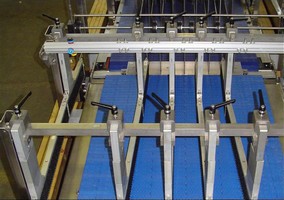

Solid-State Infeed enables low-pressure product conveying.

Engineered to eliminate line jams during packaging process, Zero-Gap II(TM) Infeed monitors and controls product movement to maintain constant low line pressure and optimize machine uptime. Complete product conveyor assembly, installed between upstream product conveyor and original infeed of machine, features flexible design and gentle handling capabilities. It distributes product from nested...

Read More »

Wrappers and Tray/Shrink Systems have film feed module.

Capable of operating speeds to 100 trays/min, Continuum film wrappers and tray/shrink systems come with direct drive film feed module for applications in food and beverage industries. Module, engineered with servos, consistently feeds, cuts, and delivers clear or printed film to wrapper wand. It also incorporates features to handle static-charged film. Open design provides access to all...

Read More »

Tray/Shrink System operates at speeds up to 100 trays/min.

Providing smooth transition during product/tray merge, Continuum(TM) Integrated Tray/Shrink System features touch screen controls and push-button grouper changeover for ease of use. Customers can choose between freestanding or integrated shrink wrapper, and integrated tray stacker option. Device is suited for both loose containers and multipacks in materials such as glass, PET, HDPE, metal, and...

Read More »

Packaging Machine eliminates lane jams.

Operating at speeds from 100 to 1,600 bottles/min, Zero-Gap infeed packaging machine incorporates precise geometry and sensors to ensure continuous container supply to downstream lanes and grouping section. Line pressure and handling properties make system suitable for compressible or hot-filled PET, lightweight glass, and aluminum. Compatible with variety of platforms, it can be programmed to...

Read More »

Case Packer offers flask handling option.

With thicker lane guides, Versatron™ Case Packer allows for safe and gentle packing of 100, 200, and 375 mL flasks. Also available, Pic-N-Place case filling module provides direct, automatic control of product and gentle placement without need for lift table, minimizing breakage and protecting labels.

Read More »

Continuous Motion Uncaser has 70 case/min capacity.

PikMore Uncaser features gripper heads that revolve around center carousel to lift empty glass bottles from their cases. Bottles are then placed on conveyor as they leave machine. Continuous motion machine includes graphic operator interface screen that enables mostly automatic operation. Programmed for auto lubrication, product also times all operations through trigger on main carousel, and is...

Read More »

Machine Operator Interface integrates color touchscreen.

Able to be customized to each Standard-Knapp machine, smart Operator Interface is graphically driven and utilizes color touchscreen technology to offer intuitive machine control. Computer-aided fault recovery minimizes mean time to recover (MTR) and promotes efficiency for 24/7 applications in food and beverage industries. Along with color-coded alerts, features include machine history display,...

Read More »

Solid-State Infeed enables low-pressure product conveying.

Engineered to eliminate line jams during packaging process, Zero-Gap II(TM) Infeed monitors and controls product movement to maintain constant low line pressure and optimize machine uptime. Complete product conveyor assembly, installed between upstream product conveyor and original infeed of machine, features flexible design and gentle handling capabilities. It distributes product from nested...

Read More »

Wrappers and Tray/Shrink Systems have film feed module.

Capable of operating speeds to 100 trays/min, Continuum film wrappers and tray/shrink systems come with direct drive film feed module for applications in food and beverage industries. Module, engineered with servos, consistently feeds, cuts, and delivers clear or printed film to wrapper wand. It also incorporates features to handle static-charged film. Open design provides access to all...

Read More »

Tray/Shrink System operates at speeds up to 100 trays/min.

Providing smooth transition during product/tray merge, Continuum(TM) Integrated Tray/Shrink System features touch screen controls and push-button grouper changeover for ease of use. Customers can choose between freestanding or integrated shrink wrapper, and integrated tray stacker option. Device is suited for both loose containers and multipacks in materials such as glass, PET, HDPE, metal, and...

Read More »

Packaging Machine eliminates lane jams.

Operating at speeds from 100 to 1,600 bottles/min, Zero-Gap infeed packaging machine incorporates precise geometry and sensors to ensure continuous container supply to downstream lanes and grouping section. Line pressure and handling properties make system suitable for compressible or hot-filled PET, lightweight glass, and aluminum. Compatible with variety of platforms, it can be programmed to...

Read More »