Advanced Machine & Engineering Co.

Rockford, IL 61103

AMLOK-® Pneumatic Rod Locks Keep A-10 Warthog Steady and Protects Technicians During Refurbish/Repair OPS at HILL AFB

Unique rod lock assemblies from Advanced Machine Engineering built into Boeing fixtures; used to stabilize airframe, maintain structural integrity during and after major repairs During the maintenance and repair operations of A-10 Warthog aircraft at Hill Air Force Base in Utah, a unique product design from Advanced Machine & Engineering (AME) helps maintain the structural integrity of this heavy...

Read More »

Hydraulic Rod Locks Assist on Movable Pool Bottom Project

Aquatic Development Group uses specially modified AmlokÃ-® product from Advanced Machine & Engineering to protect movable pool floor stability at Ithaca College Aquatic Development Group (ADG) of Cohoes, New York is a professional design, manufacturing and construction firm serving the waterpark, resort, hotel aquarium, aquatic therapy and commercial/institutional swimming pool markets. The...

Read More »

Automatic Sawing System cuts rails in 32 sec.

Operating with minimized environmental impact, AMSAWÃ-® R300R integrates rail hole drilling station for bolted joints at rail ends as well as carbide cutting blades, which accept 5 retips and up to 40 resharpenings before replacement. It includes onboard PLC, preloaded ballscrews, and 3 vertical and 2 horizontal hydraulic clamps enabling 90Ã-º cut on rail ends. Saw blade guide and...

Read More »

AME Introduces Clamping Products from Jakob Antriebstechnik

Advanced Machine & Engineering Co. (AME) is introducing several new workholding clamping products from Jakob Antriebstechnik, the company's European partner. The series MC power clamping nut offers simple manual operation, high clamping forces through force magnification and high operating safety, as a result of a self-locking feature. The clamping force ranges from 40 to 160 kN. This product...

Read More »

Rotary Unions are designed for optimized coolant flow.

Rated for 24,000 rpm max spindle speed and 80 bar max coolant pressure, OTT-Jakob GDR single-passage rotary unions are designed for OTT-Jakob power drawbars found in machine tools with high-speed spindle and in which machine tool feeds coolant through single passage to tool. Designed to fit small unclamp units, GDP unions have hybrid bearing, balanced design, and closed sealing surface. Max...

Read More »

Safety Stops secure platens under suspended load.

Activated by weight of the dropping mass, safety catcher stops and locks dropping platen via wedge mechanism located on smooth rod that can be placed in any position. Unit can be installed on hydraulic/pneumatic presses and other machines in which dropping masses must be stopped for safety reasons. Locking capability is proportioned to dropping mass, and locking position functions for entire...

Read More »

Locknuts use clamping screws with hexalobular socket head.

Suited for applications where space is limited, Spieth Type MSF Locknuts utilize clamping screws with socket head similar to TORX system screw to optimize handling, mounting, and service life of tools used for tightening. Units feature Spieth locking principle, which provides vise-like locking of locknut.

Read More »

Rotary Union features integrated leakage sensor.

Designed with permanently sealed surfaces, Rotary Union offers constant control of clamping system, preventing damage to system or spindle. Unit features max speed of 36,000 rpm, max coolant pressure of 80 bar, and max cleaning air of 10 bar. Maximum air pressure after confirmation is 5 bar and filter porosity is less than 50.

Read More »

Static Clamping System fits in tight spaces.

Featuring compact design, Model SST 60 provides exact position clamping of mechanical components like pallets or workpieces. It offers clamping force of 18 kN, clamping pressure of 80 bar, and release pressure of 50 bar. Attachment options include fixed, one-direction free (during positioning, before clamping) and 2 directions (during positioning, before clamping).

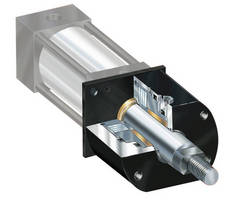

Read More »Cylinders have locking design and integral rod clamp.

Series CCA Advanced Locking CylindersÃ-® integrate AMLOKÃ-® Power Off Rod Clamp, which provides control over travel, drifting, bouncing, and reverse traveling. Equipped with oversized intensifier, products' locking force holds rod in any mid-stroke position. Clamping is accomplished through spring force, and unit is unlocked by air pressure. Product is offered as integral unit with...

Read More »Unyielding Integrity | Building Long-lasting Business Relationships with Openness and Honesty

By: Meaghan Ziemba, Marketing Communications, MackingChips In today’s hyper-competitive, digital world, consumers have access to more information than before right at their fingertips. The bar has been raised for companies in terms of honesty, transparency, and integrity and consumers quickly dismiss those that do not meet their high expectations and standards. Companies need to be...

Read More »God Honoring | The Value at The Core of Our American Manufacturing Company

By: Nick Goellner, Managing Director, MakingChips When we Honor God, Advanced Machine & Engineering lives out ALL of our core values On November 2nd, 2018, a group of manufacturing leaders gathered for the 43rd TMA annual prayer breakfast. It was a very diverse group of businessmen and women, but they all shared something -- a desire to glorify God and boldly share their faith in Christ....

Read More »Top Trends Changing The Face of Manufacturing

By: Meaghan Ziemba, Content Creator/Community Manager, Making Chips Advanced technologies continue to revolutionize manufacturing into a highly connected, highly intelligent industry where tech-savvy workers and intelligent robots develop the products and services of the future. According to a recent survey done by IQMS Manufacturing Software, manufacturers who are implementing some or all of...

Read More »Willy Goellner Named Among '2018 - People You Should Know'

By: Meaghan Ziemba, Content Marketing Manager, AME Rockford, Illinois, USA - November 5, 2018 - Advanced Machine & Engineering (AME) and Hennig, Inc. Founder and Chairman, Willy Goellner, was named one of the 2018 People You Should Know by the Rockford Chamber of Commerce. He was one of 20 people recognized during a special reception on Thursday, November 1 at the Tebala Event Center....

Read More »National Manufacturing Day: Strengthening Manufacturingâ™s Future

By: Meaghan Ziemba, Content Marketing Manager, AME This past October was not just about cooler weather, Halloween, and pumpkin-flavored everything. It also hosted National Manufacturing Day---an annual event that occurs the first Friday of October and plays a vital role in powering the next chapter of modern American production and innovation. The event began in 2011 and involved several...

Read More »Why The Manufacturing Industry Needs The Younger Generation to Succeed

Manufacturing: A Wonderful Path to Take Students met at Giovanni’s for a panel discussion. The panel was moderated by WTVO’s Eric Wilson and featured, Noah Goellner, VP of Global Business Operations from Hennig, Inc.; Tasha Mitchell-Wendorf, Project Manager from Ingersoll Cutting Tools; and Rebecca Whelan, Quality Inspector from Rockford Toolcraft. Mayor Tom McNamara kicked of the panel...

Read More »6 Takeaways from The Industrial Inbound Summit for Industrial Manufacturers

By: Meaghan Ziemba, Content Marketing Manager, AME I recently attended the Industrial Inbound Summit at the Harley Davidson Museum in Milwaukee, Wisconsin. The marketing and sales conference featured an impressive lineup of speakers that provided tips and tools on how to position your manufacturing business for success in a hyper-competitive digital world. I found a lot of the information...

Read More »Participating in National Manufacturing Day Strengthens The Workforce of Tomorrow

By: Meaghan Ziemba, Content Marketing Manager, AME Marketing Director, Nick Goellner, and Marketing Technology Manager, Kaleb Mertz, from Advanced Machine & Engineering (AME), and myself visited Auburn High School in Rockford, Illinois to speak with students on National Manufacturing Day to help strengthen the manufacturing workforce of tomorrow. Goellner and Mertz spoke with Juniors and...

Read More »Governor Raunerâ™s Keys to Making Illinois Manufacturing Advanced Again

By: Nick Goellner, Marketing Director, Advanced Machine & Engineering Support: Kaleb Mertz, Technology Manager, Advanced Machine & Engineering Manufacturers in Illinois often feel like the odds are stacked against us. There are easier places to start and grow a manufacturing business (less regulations, lower tax rates etc.), but most of us believe that change is possible here in our home...

Read More »Congresswoman Cheri Bustos Gets Hands-On with CNC Machining at AME

By: Meaghan Ziemba, Content Marketing Manager, AME Rockford, Illinois, USA - September 21, 2018 - Earlier today, Democratic Congresswoman Cheri Bustos (@RepCheri) visited Advanced Machine & Engineering to learn more about the family business and CNC machining. She also discussed some of the challenges of the manufacturing skills gap in the United States. During her visit, she toured the new...

Read More »