Quintus Technologies HIP Expands Accurate Brazingâ™s Thermal Processing Capabilities

Heat Treating Specialist Broadens Service Offering and Compresses Lead Times with New Hot Isostatic Press VÄSTERÅS, SWEDEN (PRWEB) JULY 23, 2019 Accurate Brazing, a full-service provider of specialized heat treating solutions, will add hot isostatic pressing to its thermal processing capabilities with the installation of a Hot Isostatic Press (HIP) from Quintus Technologies. The press, model...

Read More »Thriving Direct Mail and Transactional Communications Provider, DNI Corp., Expands Capabilities and Capacity with SCREEN Truepress Jet520S Inkjet Press

Rolling Meadows, Illinois and Nashville, Tennessee — DNI Corp., the Nashville-headquartered print and mail solutions company now in its 35th year, is accelerating its investment in advanced production technology with the purchase its first inkjet press: a leading-edge SCREEN Truepress Jet520S. Experiencing steady growth over the past several years, company owner, Jono Huddleston, and...

Read More »

Multicyl Now Specializing In Punching Solutions for Aluminum Extrusions

Attention fenestration and construction industries! While Multicyl and our related product lines “Press In a Box (PIB)” and “Multicyl Linear Rail (MLR)” are a familiar mainstay in the manufacturing industry, a new development is our focus on punching custom aluminum components. We have grown a knowledge base in aluminum extrusion punching applications that has allowed us to carve out a...

Read More »

Ducommun Incorporated Relies on Beckwood for Hot Forming Press Technology

St. Louis, MO – Beckwood Press Company, a leading manufacturer of custom hydraulic presses and automation systems and the Triform line of sheet hydroforming equipment, has partnered with aerospace industry leader Ducommun Incorporated to design and manufacture two new hot forming presses for Ducommun’s Parsons, Kansas facility. Since 2006, Ducommun has relied on Beckwood to provide innovative...

Read More »

Understanding Food & Beverage Lubricants

The term "food-grade lubricants" may sound like another name for food oils such as cooking spray, salad dressing, lard, or canola oil, but it actually refers to lubricants that are safe for use in food processing equipment.

Read More »

Beckwood Press Company Supplies Custom Bulge Forming Press to Fike Corporation

St. Louis, MO – Fike Corporation, a globally recognized leader in engineered solutions for process safety and facilities protection recently installed another Beckwood Press Company hydraulic press. When Fike needed a new press to accommodate their expanding product line, they again turned to Beckwood Corporation, their trusted solutions provider. Fike’s previous success with Beckwood and...

Read More »

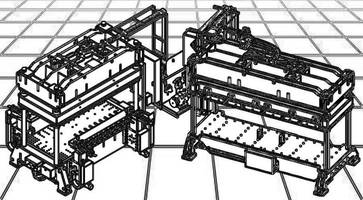

Beckwood Press Company Supplies 3-Press Package to Railroad Industry Leader

St. Louis, MO – Beckwood Press Company recently manufactured three bulldozer presses for one of the world’s largest suppliers of railroad and transit system products. The new 3-press package will be used to form, straighten and bend I-beams to support the improvement of railway infrastructure. In total, this railroad industry leader now relies on seven Beckwood presses in their daily forming...

Read More »

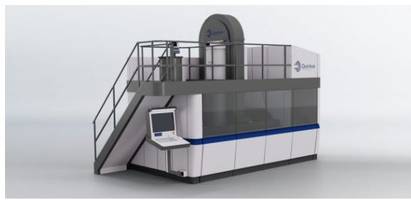

Sheet Hydroforming Presses feature integrated tool change.

In addition to optimized pressure containment system that improves cycle times, Triform Deep Draw BD Series is equipped with ergonomic tool change system that minimizes changeover times. Cartridge-style chamber is conveyed through rear opening of press, presenting blank holder and punch to operator. Presses can convert from Deep Draw configuration to Fluid Cell configuration, for shallow forming...

Read More »

Hammer Packaging Invests in the Future with a Mark Andy P7 and Rotoflex VLI

New additions expand its printing and converting capabilities St. Louis, Missouri, USAÃ- – Hammer Packaging, an established leader in labels and package decoration products, has installed a Mark Andy Performance Series P7 press along with a Rotoflex VLI 440 finishing system. The new 17-inch, 10-color P7 press includes combination hot air drying/UV curing, a Mark Andy QCDC™ (Quick Change...

Read More »Screen Truepress Jet L350UV Expands Opportunities for Short-Run Labels and Folding Cartons at Lithotone

ROLLING MEADOWS, Illinois — Three key factors in recent years have been cited as driving demand for inkjet label presses: production efficiencies, especially for short and medium run lengths; the power of digital inkjet presses to enable variable data printing; and advances in jetting assemblies that have significantly improved print quality and reliability. Lithotone Inc. in Elkhart, Indiana,...

Read More »

AccuWeb EVO 150 Aids Precise Registration on New High-Speed Digital Colordyne Press

New Colordyne digital press runs at record speed with highest resolution thanks to highly responsive and accurate web guiding. Madison, Wis. — The new Colordyne Technologies' (CDT) 3600 Series digital color press is the fastest press of its kind with 1600 x 1375 resolution. At 225 fpm, precise web guiding is not only critical in maintaining perfect print registration on the CDT 3600 Laser Pro's...

Read More »

Sentry Equipment Introduces New Compact Hygienic Automatic Sampler

As a leader in industrial sampling equipment at Sentry Equipment, our success is built on a history of innovation and designs that epitomize value and efficiency. The new Hygienic Automatic Sampler is another example of our dedication to developing quality engineered products. To learn how this product can streamline the sampling process for dry, free-flowing materials, see our new video.

Read More »