Ducommun Incorporated Relies on Beckwood for Hot Forming Press Technology

St. Louis, MO – Beckwood Press Company, a leading manufacturer of custom hydraulic presses and automation systems and the Triform line of sheet hydroforming equipment, has partnered with aerospace industry leader Ducommun Incorporated to design and manufacture two new hot forming presses for Ducommun’s Parsons, Kansas facility.

Since 2006, Ducommun has relied on Beckwood to provide innovative forming solutions for their toughest manufacturing challenges. Upon completion of these presses, Ducommun will have six Beckwood machines, further strengthening the alliance between the two companies. With anticipated delivery in May 2016, the fifth Ducommun press will be instrumental in hot forming titanium parts for a variety of aerospace platforms, including the new Boeing 737 MAX aircraft.

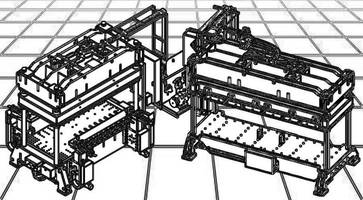

Highlights of this 200-ton custom press include a pneumatic dwell system which allows the primary electric motor and pump to be “turned off” during the extended dwell cycle for improved energy efficiency, dual linear and pressure transducers in the main ram cylinders for optimal reliability and redundancy, and precision speed control to regulate ram speeds as low as 1/8 IPM (inches per minute).

The sixth machine, a 570-ton hot forming / super plastic forming press, will be used to form titanium structures for the Airbus A320 aircraft. Special features of this press include an automatic insulated door system for loading and unloading without adversely affecting the press’ operating temperature, a bed shuttle system for loading and unloading parts and tooling, and Beckwood’s proprietary Active Level Control System (ALC) which uses closed-loop monitoring and control to maintain bed-to-ram parallelism and reduce the effects of off-center loading.

In addition to hot forming, this press will also have capabilities for Superplastic Forming (SPF). SPF, a valuable tool for the fabrication of complex parts in the aerospace and automotive industries, uses hightemperature argon gas pressure to form high-strength materials into net shapes in a single operation.

“Beckwood’s goal is to forge long-term partnerships with every customer,” said Beckwood President, Jeffery Debus. “These two new hot forming presses solidify our commitment to Ducommun’s continued success while providing them with technologically-advanced machines to enhance their forming capabilities.”

About Ducommun Incorporated

Ducommun Incorporated delivers innovative manufacturing solutions to customers in the aerospace, defense and industrial markets. Founded in 1849, the company specializes in two core areas – Electronic Systems and Structural Systems – to produce complex products and components for commercial aircraft platforms, mission-critical military and space programs, and sophisticated industrial applications.

For more information, visit www.ducommun.com.

Beckwoodpress.com l Triformpress.com l 889 Horan Drive l  Fenton, MO 63026 - USA l 636-343-4100

About Beckwood Press Company

Beckwood Press Company is a leading hydraulic press manufacturer, located in St. Louis, MO USA. They offer quality, custom hydraulic presses for virtually every industry and application, including a line of temperature controlled presses for compression molding, composite forming and high-temperature Hot Forming / SPF applications. Beckwood also manufactures the Triform line of Sheet Hydroforming Presses in both Fluid Cell and Deep Draw configurations, hydraulic ring expanders / sizers, hot joggle presses, as well as a line of stretch forming machines for both extrusion, sheet / leading edge applications. Get the latest news from Beckwood at http://www.beckwoodpress.com/news.

Contact: Christie Williams

800-737-0111 (ext. 133)

info@beckwoodpress.com