Plastic Pellet Classifiers feature double deck design.

Press Release Summary:

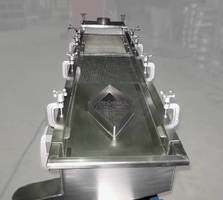

Available on Witte 700 Series classifiers, diamond double deck design screens product twice through dual, perforated decks for optimal removal of off-spec pellets. Diamond-shaped openings in first stage screening deck provide constant access to pellet flow in second stage screening deck below to monitor flow during operation, enabling blockages to be quickly found and removed. By quieting pellets into single layer, vibratory technology helps prevent short-longs from contaminating end product.

Original Press Release:

New Diamond Deck Classifier Design Provides Constant Access to Second Pellet Screening Deck

Witte Innovation Makes Blockages Easy to Find, Easy to Clear

Washington, NJ – A new, diamond, double deck plastic pellet classifier design developed by process equipment manufacturer The Witte Co., Washington, New Jersey (www.witte.com) features diamond-shaped openings in the first stage “overs” screening deck that provide constant access to the pellet flow in the second stage “overs” screening deck below to monitor the flow during operation. Any blockages may be quickly found and removed.  Â

Available on the Witte 700 Series classifiers, the diamond, double deck design screens the product twice through dual, perforated decks for superior removal of off-spec pellets while the company’s proprietary vibratory technology quiets the pellets into a single layer to help prevent “short-longs” from contaminating the end product. “Short-longs” meet pellet diameter specifications but not length.

For more information, contact Larry Stoma, the Witte Company, Inc.; 507 Rt. 31 South, Washington, NJ, 07882; 908-689-6500; Fax 908-537-6806; LarryStoma@witte.com; http://www.witte.com