Thermally Conductive Epoxy serves applications up to 572°F.

Press Release Summary:

Used for bonding, potting, tooling, and molding, Aremco-Bond™ 805 adheres to high-temperature plastics, glass, ceramic, and high-expansion metals. This 2-component, 100% solids, aluminum-filled epoxy cures at room temperature in 24 hr with final cure at 200°F in 2 hr. Cured material exhibits thermal conductivity of 12.5 Btu-in/hr-ft²-°F and dielectric strength of 50 V/mil. Respective tensile shear and flexural strengths are 1,800 and 15,500 psi, and Shore D Hardness is 87.

Original Press Release:

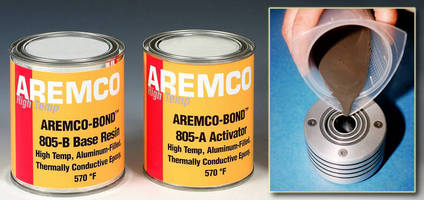

Aremco-Bond 805 High Temp Thermally Conductive Epoxy Now Available

Aremco-Bond™ 805, a new high temperature, thermally conductive epoxy system developed by Aremco Products, Inc., is now for bonding, potting and molding applications to 300 ºC (572 ºF).

Aremco-Bond™ 805 is a two component, 100% solids, aluminum-filled, epoxy ideal for bonding, potting and tooling applications to 300 ºC (572 ºF). Aremco-Bond™ 805 exhibits excellent adhesion to a variety of high temperature plastics such as polyimides and composites, as well as glass, ceramic, and high expansion metals.

Aremco-Bond™ 805 is mixed in a ratio of 10 parts resin to 1 part activator by weight and cures at room temperature in 24 hours with a final cure at 200 ºF in 2 hours. Cured material exhibits a thermal conductivity of 12.5 Btu-in/hr-ft²-ºF and dielectric strength of 50 volts/mil. The tensile shear and flexural strengths are 1,800 and 15,500 psi, respectively. The linear shrinkage is .003 in/in and Shore D Hardness is 87.

Aremco-BondЀ 805 is easily machined, drilled, tapped, or polished. Typical applications include the bonding of heat sinks and fins used in heat exchangers as well as producing vacuum molds, dies, drill jigs, injection molds, and other high temperature fixtures. Aremco-Bond™ 805 is supplied in pre-measured pint, quart, gallon and five gallon containers from stock.

Please contact Aremco's Technical Sales Department for more information about this advanced product.

Technical technical@aremco.com

Orders orders@aremco.com

Pricing quotes@aremco.com

MSDS msds@aremco.com