Microscope offers non-contact 3D material analysis.

Share:

Press Release Summary:

Confocal Laser Scanning Microscope, Model LSM 5 PASCAL includes functions for quantitative surface analysis and characterization such as roughness and volumetric measurement as well as bearing ratio analysis. Units are available with Axio Imager MAT upright stand or Axiovert 200 MAT inverted stand. Both can employ piezotechnology for precise measurements of nanometer-scale height steps. StitchArt software allows large profiles and topographies to be recorded.

Confocal Laser Scanning Microscope, Model LSM 5 PASCAL includes functions for quantitative surface analysis and characterization such as roughness and volumetric measurement as well as bearing ratio analysis. Units are available with Axio Imager MAT upright stand or Axiovert 200 MAT inverted stand. Both can employ piezotechnology for precise measurements of nanometer-scale height steps. StitchArt software allows large profiles and topographies to be recorded.Original Press Release:

Zeiss LSM 5 PASCAL for Flexible, Non-Contact 3D Materials Analysis

Thornwood, NY - Carl Zeiss introduces a new version the LSM 5 PASCAL confocal laser scanning microscope for materials research and quality inspection. Outstanding performance capabilities of the existing system have been extended with special functions for quantitative surface analysis and characterization such as roughness and volumetric measurement as well as bearing ratio analysis.

The new LSM 5 PASCAL is available with two microscope stands: Axio Imager MAT upright and Axiovert 200 MAT inverted. Latter allows non-contact 3D materials analysis on large-surface and bulky specimens. Both stands are capable of employing piezotechnology for quick and precise measurements of nanometer-scale height steps.

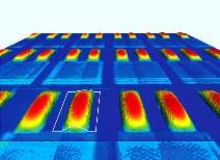

New StitchArt software allows large profiles and topographies, extending over more than 100 times the microscope's scanning field, to be recorded with high resolution. This enables the LSM 5 PASCAL to acquire and measure arrays of highly resolved image stacks containing long-strip assembled height profiles and large-area segments of materials sample surfaces. Whether roughness or waviness analysis, thin films or steep edges, micro or macro-scale - the StitchArt option matches the imaging frame size to the application, thus broadening the horizons of microscopy.

An expanded topography package considerably improves the capabilities for non-contact optical 2D and 3D surface analysis. In addition to the convenient acquisition, processing and presentation of XYZ image stacks, the package now also allows recording of XZ profiles along a straight line or free-hand curve.

Topographic animations can be generated and exported in all 3D presentation modes. Complete processing runs including filtering, fitting and least-squares algorithms are saved as parameter files to be available for later reuse.

For more information contact Carl Zeiss MicroImaging, Inc., Thornwood, NY 10594, 800-233-2343, www.zeiss.com/micro, or email at micro@zeiss.com

Carl Zeiss is a leading international group of companies operating worldwide in the optical and opto-electronic industry. Carl Zeiss AG is headquartered in Oberkochen, Germany. The Carl Zeiss Group consists of six business units that operate with sole responsibility. They are generally ranked first or second in the three strategic markets of biomedical research and medical technology, system solutions for semiconductor, automotive and mechanical engineering industries, and optical consumer goods such as eyeglass lenses, camera lenses and binoculars.

The Carl Zeiss Group is directly represented in more than 30 countries and operates production facilities in Europe, America and. Asia. In fiscal year 2002/03 the global workforce of approximately 14,000 employees generated revenue of about EUR 2 billion. Further information is available at www.zeiss.com.