Diesel Hydraulic Control from Rexroth Combines Diesel Engine and Hydraulics Control

Dream combination: Higher dynamics at lower engine speeds

High dynamic response of the travel drive and implement hydraulics on mobile work equipment even at reduced diesel engine speeds and for TIER 4 final engines: This is the goal Rexroth has achieved with their electronic BODAS system solution called "Diesel Hydraulic Control". Developed together with the diesel engine specialists from BOSCH, the world's largest automotive supplier, this solution for engine management and as well as drive and working hydraulics reduces diesel fuel consumption by up to 20 percent.

The TIER 4 emissions regulations for mobile work equipment due to take effect starting in 2014 will likely result in significantly poorer load response of diesel engines. Furthermore, manufacturers of excavators, telehandlers, and other mobile work equipment are reducing the engine speeds in order to consume less diesel fuel. The control devices used until now for the drive and working hydraulics cannot compensate for this "sluggishness". The potential risk is lower productivity.

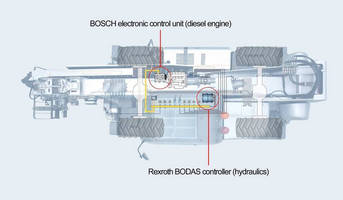

With Diesel Hydraulic Control (DHC) Rexroth has teamed with BOSCH to develop a new control strategy which retains the accustomed lively response of the travel drive and implement hydraulics even under conditions of diminished load response and lower engine speeds. DHC changes the traditional function sequence and lets the diesel engine know of expected load requirements. This is accomplished using matched controllers from Bosch for engine management and from Rexroth for the travel drive and implement hydraulics, using a common special map. This DHC system map represents the vehicle-specific relationships between rpm's, efficiency and torque.

Diesel Hydraulic Control continuously determines the demands of the travel drive and implements hydraulics and uses this information to dynamically calculate the optimal operating points for the diesel engine and hydraulic components by means of the DHC system map. In practice, the joystick for the implement hydraulics for example transmits pending work requirements directly to the DHC, which in turn passes this requirement to the diesel ECU. This allows the engine time to prepare for the imminent mechanical load. The world's first combined controller solution compensates in this way for the expected poorer load response of TIER 4 final diesel engines. At the same time DHC makes it possible to operate the equipment at the accustomed dynamic response levels in spite of lower engine speeds, thereby saving fuel.

Since DHC means that the diesel engine only provides as much power as the machine actually needs at any given moment, diesel fuel consumption is reduced compared with current figures. Fuel savings of up to 20 percent as measured in real-life testing will reduce the total cost of ownership for operators with no sacrifice in dynamic response of the travel drive and implement hydraulics.

Bosch Rexroth AG is one of the world's leading specialists in the field of drive and control technologies. Under the Rexroth brand name, the company supplies more than 500,000 customers with tailored solutions for driving, controlling, and moving. Bosch Rexroth is a partner for Mobile Applications, Machinery Applications and Engineering, Factory Automation and Renewable Energies. The company provides customized solutions tailored to the needs and specifications of each individual market. As The Drive & Control Company, Bosch Rexroth develops, produces, and sells components and systems in over 80 countries. As part of the Bosch Group, Bosch Rexroth and its 34,900 associates generated approximately 5.1 billion euros in revenue ($6.8 billion) in 2010. To learn more, please visit www.boschrexroth-us.com

The Bosch Group is a leading global supplier of technology and services. In the areas of automotive and industrial technology, consumer goods, and building technology, some 285,000 associates generated sales of 47.3 billion euros ($62.7 billion) in fiscal 2010. The Bosch Group comprises Robert Bosch GmbH and its more than 350 subsidiaries and regional companies in over 60 countries. If its sales and service partners are included, then Bosch is represented in roughly 150 countries. This worldwide development, manufacturing, and sales network is the foundation for further growth. Bosch spent 3.8 billion euros (approximately $5 billion) for research and development in 2010, and applied for over 3,800 patents worldwide. With all its products and services, Bosch enhances the quality of life by providing solutions which are both innovative and beneficial. Bosch is celebrating its 125th anniversary in 2011. Additional information can be accessed at www.bosch.com, www.bosch-press.com, and 125bosch.com.

Keep in touch with Rexroth by "liking" us on Facebook at www.facebook.com/BoschRexrothUS and following us on Twitter at twitter.com/BoschRexrothUS.