Victrex USA, Inc.

Suite 120

West Conshohocken, PA 19428

Victrex Delivers Security of Supply as Airplane Production Ramps Up

Readiness Confirmed with Material Certification and Stocking Program for VICTREXÃ-® PEEK Polymers WEST CONSHOHOCKEN, PA, USA - Victrex Polymer Solutions, the world leader in high performance polyaryletherketones, has reaffirmed its security of supply in anticipation of increased demand as commercial airplane manufacturers plan to boost production rates to record levels. Victrex issued a...

Read More »Magma Global and Victrex Collaborate to Develop Next Generation Solutions for Deep Water Transfer of Subsea Oil and Gas

British firms develop cutting-edge technology to tap estimated potential market of $13.9 billion per year Thornton Cleveleys, UK- Victrex Polymer Solutions, a division of Victrex plc, the world's leading manufacturer of high performance polyaryletherketones, and Magma Global Ltd. have signed a collaboration and exclusive material supply agreement that will enable the two companies jointly to...

Read More »Victrex Polymer Solutions Reinforces Its Focus on Composites

WEST CONSHOHOCKEN, PA, USA - Victrex Polymer Solutions has strengthened its composites business focus and has established a worldwide task force to offer an array of technical resources to assist engineers both at the processor and end-user level in order to address specific requirements within the composite area. The pressure to reduce weight, enhance reliability and durability, reduce...

Read More »

VICTREX-® PEEK(TM) Polymer Used in Suprem Prepreg Tape Designed for Automated High Speed Production

WEST CONSHOHOCKEN, PA, USA - Victrex Polymer Solutions, a division of Victrex plc announced that Suprem SA, a Swiss-based prepreg manufacturer, has reported a more than 50% annual growth in its business, which was generated from prepregs made with VICTREXÃ-® PEEK(TM) polymer. SupremÃ-'s proprietary impregnation method allows for the rapid and flexible production of an extensive variety of...

Read More »

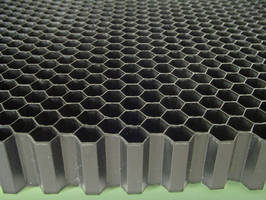

New Lightweight Honeycomb Structure Made with Victrex APTIV(TM) Film Fills Performance Gaps, While Enhancing Design Freedom and Reducing Production Costs

WEST CONSHOHOCKEN, PA, USA - PlastiCell of France announced that it has developed an innovative process for the production of lightweight thermoplastic honeycomb structures using Victrex APTIV(TM) film. The unique design of PlastiCell's honeycomb provides an ideal solution for aerospace and other industries seeking to reduce weight while maintaining high levels of strength and stiffness. APTIV...

Read More »

High Temperature Resistant VICTREX-® PEEK(TM) Polymer Replaces Stainless Steel Valves and Housings in Beverage Bottling Machines

The change in material increased equipment lifespan, reduced downtime, and increased overall productivity WEST CONSHOHOCKEN, PA, USA - Solidur, one of Brazil's largest high-performance plastics processing companies, has selected VICTREXÃ-® PEEK(TM) polymer, manufactured by Victrex Polymer Solutions, a division of Victrex plc and leading provider of high performance polyaryletherketones, to...

Read More »

Liners Made with Victrex-® Peek(TM) Polymer Extend Tubular Life in Aggressive Downhole Environments

WEST CONSHOHOCKEN, PA, USA - (April 8, 2009) When Western Falcon of Houston, Texas, USA, a major manufacturer of tubular linings for downhole applications, wanted to design a new high-performance seamless thermoplastic liner, it chose VICTREX-® PEEK(TM) polymer because of its unique combination of tensile strength, chemical resistance, ductility, temperature capabilities and resilience. The new...

Read More »

Victrex Aptiv(TM) Film Enables Thinner Prepregs than Traditional Carbon Fiber Composite Materials

WEST CONSHOHOCKEN, PA, USA - (March 9, 2009) - By using Victrex APTIV(TM) film as the matrix polymer, Mitsuya, a Japanese developer of carbon fiber composite materials, has developed an innovative prepreg sheet that is thinner - 40Ã-µm or less - enabling lighter weight and higher performance than traditional carbon fiber composite materials. Carbon fibers are manufactured into tows consisting...

Read More »

Driving System Made with VICTREX-® PEEK(TM) Polymer Delivers Higher Performce in New Generation of Water Powered Dosing Pumps

WEST CONSHOHOCKEN, PA, USA - (February 26, 2009) - When Dosatron International, a global leader in water powered dosing pumps, wanted to simplify the design of its newest generation of pumps (Dosatron-® D3 series), it chose VICTREX-® PEEK(TM) polymer for the driving system. The polymer's exceptional mechanical properties enabled Dosatron to engineer a highly innovative series of high precision...

Read More »

Mitsuya's PrePreg Sheets Made with Victrex APTIV(TM) Film, Thinner than Traditional Carbon Fiber Composite Materials

Tokyo - Victrex Japan, Inc, a subsidiary of Victrex plc, an innovative leading manufacturer of high performance materials, including VICTREXÃ-® PEEK(TM) polymer, VICOTEÃ-® Coatings and APTIV(TM) films, announced that Mitsuya, a company developing carbon fiber composite materials, has developed a prepreg sheet with thinner layers than a traditional one by using Victrex's APTIV Films....

Read More »Victrex plc Investment to Create a Joint-venture for Peek Manufacture in China

Development of PEEK polymer capacity in China sets the stage for further regional growth opportunities and further differentiates Victrex’s range of PEEK and PAEK grades Thornton Cleveleys, UK - (January 14, 2020) - Victrex plc today announces the creation of a joint-venture between its subsidiary, Victrex Hong Kong Limited, and Yingkou Xingfu Chemical Company Limited, to build and operate a...

Read More »Victrex Awarded Important Automotive Quality Standard for Manufacture of Gears

USA design and manufacturing facility proves its power to perform: PEEK polymer-based gear solutions available for both ICE & Electric Vehicle Powertrain platforms, and also, on display at K 2019 tradeshow Thornton Cleveleys, UK - (August 8, 2019) - Victrex, an innovative world leader in high performance PEEK and PAEK polymer solutions, has achieved a new milestone for its automotive...

Read More »Victrex and Bond Pioneer 3D Printing for PAEK Parts with Maximized Performance

Advancing additive manufacturing processing technology for existing grades of high performance VICTREX™ PAEK and PEEK-OPTIMA™ polymer THORNTON CLEVELEYS, UK - (March 13, 2019) - To help customers with an accelerated route to market for 3D printed PAEK parts, UK-based Victrex has commenced a multi-million Euro investment in Bond High Performance 3D Technology. The Dutch company has developed...

Read More »Victrex and Coriolis Composites to Unlock Efficiency Potential for Thermoplastic Composites Parts

Unidirectional tape (UDT) prepreg technology achieves unprecedented lay-up speed for thermoplastic UDT Thornton-Cleveleys, UK - (March 5, 2019) - Victrex and Coriolis Composites have teamed up to push the boundaries of thermoplastic unidirectional tape (TP UDT) prepreg lay-up and consolidation and improve the manufacturing efficiency of composite parts. At the JEC World Technical Conferences...

Read More »Victrex Invests in State-of-the-Art Technology with Surface Generation

Injection and compression molding technology expected to benefit Victrex’s selected ‘parts’ programs Thornton-Cleveleys, UK - (February 6, 2019) - An innovative and differentiated tooling design and processing technology called PtFS (Production to Functional Specification), from UK-based Surface Generation, has been chosen by Victrex as it seeks to bring enhanced manufacturing...

Read More »Innovation Never Stops: Victrex Celebrates 40 Years of Peek Success, with Much More to Come

THORNTON CLEVELEYS, UK - (December 4, 2018) - November 1978 marked the invention of PEEK, a new high-performance polymer (HPP). The following 40 years blazed a trail of pioneering innovation, across a range of industries and often in demanding applications that initially seemed an unlikely candidate for the thermoplastic. The dynamic driver of the success of this versatile, breakthrough polymer...

Read More »ITHEC: Thermoplastic Composites Conference to Highlight PAEK Composite Research Results and Innovation

How PAEK thermoplastic composites and related hybrid overmolding processes can open a broader range of manufacturing options for aerospace parts will be one of the central topics at the “ITHEC 2018 - 4th International Conference & Exhibition on Thermoplastic Composites”, October 30th-31st in Bremen, Germany. Several companies, including Victrex, will present their results on the potential of...

Read More »Victrex at Fakuma Show: Pioneering Polymer Solutions and Successes

Driving innovations and progress based on high-performing PAEK and PEEK thermoplastic polymers THORNTON CLEVELEYS, UK – (October 2, 2018) – At the Fakuma show in Germany (October 16-20), Victrex, a world leading PAEK expert, is providing further proof points that the company is more than “just” a high- performance polymer (HPP) producer. A new broad food grade portfolio, a novel solution...

Read More »Victrex and the University of Exeter Invest In Making the Prospect of PAEK Additive Manufacturing a Reality

THORNTON CLEVELEYS, U.K. (PRWEB) SEPTEMBER 10, 2018 Taking on the challenge to develop a broader platform for new and existing additive manufacturing (AM) technologies, the University of Exeter (UK) and Victrex, a world leader in high-performance Polyaryletherketone (PAEK) polymer solutions, have commenced work in a strategic partnership. The goal is to introduce next-generation PAEK polymers...

Read More »Thermoplastic Composites Vital to Drive Aerospace Build Rates - Over 35,000 New Aircraft within 20 Years

“Speed of aircraft manufacture is a vital factor that will increase adoption of thermoplastic composite technologies,” commented Victrex CEO during JEC Show. THORNTON CLEVELEYS, UK - (March 12, 2018) - The aircraft industry has forecast that over 35,000 new aircraft will be required within the next 20 years. Meeting this kind of escalating demand clearly calls for new approaches and new...

Read More »