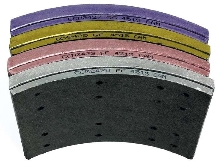

Washington Mills Distributes Products for Brake Pad and Friction Markets

Washington Mills, a leading manufacturer of abrasive grain and fused minerals, is pleased to announce a new line of distributed products for use in the brake pad and friction markets. The products are: copper sulphide, red iron oxide, black iron oxide, manganese compounds, chromite, calcium fluoride and muscovite. Please visit our website at http://www.washingtonmills.com/applications/brake-pad/...

Read More »

Friction Materials maximize brake torque.

CCM(TM) materials, based on CM24(3)(TM) friction formulation concepts and material technology, minimize stopping distances and increase lining and drum life. Suited for severe or regular use, CM24(3)(TM) is FMVSS121 axle rated from 23,000-29,000 lb. Conformability characteristics, transfer film, and cohesive technology create controlled and conditioned brake surface interface. Metallic matrix...

Read More »Friction/Wear Material suits non-lubricated applications.

Polyamide-imide TORLON(R) 4435 PAI provides wear resistance in high-PV, 50,000 to 100,000 psi-ft/min applications. It also exhibits wear resistance in low-pressure, high-velocity conditions (125 psi and 800 ft/min) and high-pressure, low-velocity conditions (2,000 psi and 50 ft/min). Glass transition temperature allows parts to operate continuously at temperatures up to 260 deg C. Thermoplastic...

Read More »

Next-Gen Nanoparticle Arc Shields

This white paper provides an overview into integrating nanoparticles into Paulson face shields.

Read More »

Do You Have Unique Lifting Needs?

EZRig Cranes offers lifting solutions that are engineered for robust performance, providing the ultimate in portability. Designed for real-world lifting needs, our products are small and light with options and features that make them ideal for a broad range of applications. See our video to learn how an EZRig Crane can simplify your lifting requirements.

Read More »