Wisconsin Oven Ships Annealing Furnace to Firearm Manufacturer

EAST TROY, WISC. (PRWEB) SEPTEMBER 28, 2018

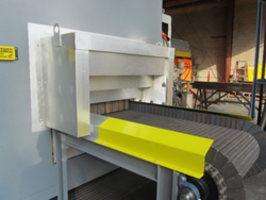

Wisconsin Oven Corporation announced the shipment of an electrically heated annealing furnace to a firearms manufacturer. This conveyor furnace will be used for annealing an assortment of brass and bronze firearm caps.

The annealing furnace has a maximum temperature rating of 760° C (1,400° F) and a normal operating temperature of 300° to 650° C (572° to 1,202° F). The work chamber dimensions are 3'0" wide x 9'0" long x 6" high. The conveyor furnace, when preheated, has the sufficient capacity to heat 225 kg of product per hour from 23° C to 650° C.

The recirculation system was designed with bottom-up airflow. The continuous conveyor system utilizes a pintle chain driven wire mesh belt and variable frequency drive for adjustable conveyor speeds. High temperature profile curtains with external vestibules on both ends of the conveyor reduce heat spill out and improve temperature uniformity. A guaranteed temperature uniformity of ±10° C at 300° & 650° C (±18° F at 572° & 1,202° F) for a minimum of 33 minutes was documented.

“This conveyor furnace was designed with features to maximize temperature uniformity throughout the work chamber to ensure optimal part results for the customer.”

-Tom Trueman, Senior Application Engineer

Unique features of this annealing furnace include:

- Guaranteed temperature uniformity of ±10° C at 300° & 650° C

- Wisconsin Oven’s patented high efficiency Expandable Surface™ design

- High temperature profile curtains a both ends of the conveyor

- Variable frequency drive for conveyor system

- Programmable temperature controller with fast acting auto-tune

- High limit controller

- Proof of conveyor movement sensor

This annealing conveyor furnace was fully factory tested and adjusted prior to shipment from our facility. All safety interlocks are checked for proper operation and the equipment is operated at the normal and maximum operating temperatures. An extensive quality assurance check list was completed to ensure the equipment met all Wisconsin Oven quality standards.

About Wisconsin Oven

Wisconsin Oven Corporation has been designing, engineering, and manufacturing industrial ovens and other heating equipment since 1973. Their custom and standard industrial ovens are used for a multitude of applications including heat treating, finishing, drying, and curing. Many of the industries they serve require specific temperature uniformity and equipment performance documentation. Their experienced design team can meet even the most stringent standards for their customers’ equipment. Wisconsin Oven realizes that the success of the company depends on their Championship team of employees, which is why they have developed a company culture that recognizes and rewards employees. The goal at Wisconsin Oven is to outperform competition and provide customers with outstanding products and service.

Wisconsin Oven is owned by Thermal Product Solutions (“TPS”), a leading American manufacturer of industrial ovens, furnaces, pharmaceutical sterilizers, laboratory ovens, environmental temperature chambers, and stability test chambers. TPS provides thermal processing and test solutions for a range of industries. TPS brands include Baker Furnace, Blue M, Gruenberg, Tenney, Lindberg, Lunaire, MPH, and Wisconsin Oven. For more information on equipment solutions from TPS visit the website at http://www.thermalproductsolutions.com.