Welding Nozzle Coating Service produces self-cleaning nozzles.

Press Release Summary:

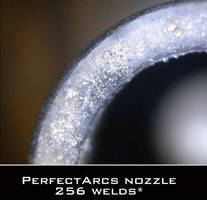

Secoa technology processes untreated welding nozzles supplied by customers and transforms them into PerfectArcs(TM) nozzles with extended life design to minimize nozzle cleaning time for any manual or robotic MIG welding process. Self-cleaning PerfectArcs(TM) nozzles eliminate need for labor-intensive spatter release sprays and dips. Products shed spatter, permitting shielding gas to flow properly and ensuring proper, clean welds.

Original Press Release:

Introducing a New Way to Fight Costly Welding Nozzle Spatter Buildup

New self-cleaning welding nozzles improve welds, may cut nozzle cleaning times by up to 80%, and are guaranteed to last 3 to 15 times longer than ordinary welding nozzles. DALTON, GA - 28 September 2009 - A new series of self-cleaning welding nozzles was introduced today by Secoa Technology of Dalton, Georgia. Designated PerfectArcs(TM) self-cleaning welding nozzles, these new weld nozzles are ideal for virtually any manual or robotic MIG welding process-including operations using tandem and/or custom weld nozzles. PerfectArcs self-cleaning nozzles eliminate the need for labor-intensive spatter release sprays & dips and are guaranteed to last 3 to 15 times (or more) longer than ordinary nozzles. To help predict the saving potentials that may result from the use of self-cleaning nozzles, a free Nozzle Cost Reduction analysis program is offered. In some manual welding operations, PerfectArcs nozzles may add up to $100,000 or more to a company's bottom line-by reducing the number of nozzles required and by significantly reducing nozzle cleaning times associated with welding spatter. Welding spatter consists of small semi-molten metallic deposits [typically comprised of iron, aluminum, and silicon] that originate from the welding wire as well as from the alloys being welded. During the welding process, it is the job of the welding nozzle to direct the flow of the shielding gas to protect the weld puddle from the atmosphere and contaminants. When the welding process is stopped and the flow of the shielding gas terminated, the semi-molten deposits becomes exposed to gases in the atmosphere--including oxygen. Spatter then can form on the inside of the welding nozzle where it can prevent proper flow of the shielding gas. A PerfectArcs self-cleaning welding nozzle easily sheds the spatter--and thus permits the shielding gas to flow properly so it can do its job of insuring proper [clean] welds. Guaranteed to fit Secoa technology does not "manufacture" weld nozzles. Instead, Secoa processes the untreated welding nozzles that customers are now using and transforms those nozzles into PerfectArcs nozzles. No-risk Nozzle Cost Reduction kit Secoa Technology will provide qualifying companies and corporations (with a present annual requirement of 500 nozzles or more) a Nozzle Cost Reduction (NCR) kit which has a one-time kit fee of $75.00 (U.S. dollars). Included in the NCR kit are six PerfectArcs nozzles (which have been transformed from customer-supplied nozzles), three suggested testing standards, and test data reporting forms. Customers may test PerfectArcs nozzles in any manner that they choose-and if their test results do not indicate that PerfectArcs nozzles will last at least 3 to 15 times longer and require significantly less cleaning time than their present nozzles, 100% of their payment will be refunded. Complete details describing PerfectArcs self-cleaning nozzles and the PerfectArcs NCR kit can be found at www.PerfectArcs.com. Backgrounder PerfectArcs(TM) is the brand name of a product that was developed and is being marketed by Secoa Technology of Dalton, Georgia. Secoa Technology was founded in 1964 by current President Wayne Snyder who has an extensive background in the metal finishing industry. Mr. Snyder developed his business to meet the growing need for specialty coating and plating in the industry. Originally known as Southeastern Coatings, the name was later shortened to Secoa, and the company has grown to be a leader in the high performance industrial coating market. In June of 2003 the company was acquired by Textile Rubber & Chemical Company, a diversified leader in the chemical industry specializing in latex, polymers, and urethane products worldwide. At Secoa's environmentally compliant and recently expanded 60,000 square foot facility, Secoa provides quality finishing, fast turnaround, and fair market pricing. The Secoa management team has over 140 years of combined experience in the finishing industry. Secoa continues to grow, servicing customers and positively impacting the industry by innovating in the areas of applied high performance coating and plating. Other Secoa Technology anti-slag and anti-spatter products: Armordize(TM) Armordize is an Aluminum Oxide conversion coating that is ideal for protecting aluminum components of weld test fixtures. This extremely hard coating is resistant to abrasion or chipping and can be applied to virtually any aluminum component to protect it from the weld spatter and slag that is common in every welding operation. FluoroClad SDFC(TM) FluoroClad SDFC is a metallic reinforced polymer coating system designed specifically to repel weld splatter. "The SDFC coating is nothing short of amazing," according to Don Peters, Vice President and General Manager of Tennessee Rand Company. "We continually look for innovative, world class solutions to the issues that our customers face. Spatter build up can be a maintenance nightmare", explains Peters. "Picture your customer taking a hammer and a chisel to chip weld splatter off the new fixture you just installed for them. This was a serious problem for our customers." "Secoa Technology worked with us to develop and come up with the SDFC coating." We tested it in our shop, showed our customers, and it quickly became a standard feature on all Fixtures from Tennessee Rand- problem solved." Other Secoa Technology Processes: Powder coating Wet coating Coating on plastics Metalizing Fluoropolymers Diamonite® hard plating