Wafer Dryer includes HCl and HF injection capability.

Press Release Summary:

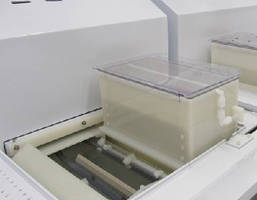

Available as option in fully automated Evolution wet processing systems and semi-automated Revolution batch wet processing systems, Genesis Xi Marangoni Dryer enables gentle, high-purity drying of semiconductor wafers with low particle contamination. Multistep oxide or ionic cleaning eliminates air interface, producing optimized surface conditioning with no damage to photoresist. Dryer minimizes use of Nitrogen gas and provides high drying performance in 7–20 min.

Original Press Release:

MEI Wet Processing Announces Integrated Marangoni Dryer with HCl and HF Injection Capability

MEI's Genesis Xi dryer produces superior surface conditioning for semiconductor processing.

ALBANY, Ore., -- MEI Wet Processing Systems and Services LLC (MEI) http://www.meillc.com announces an integrated high performance Marangoni dryer with HF and HCl injection for its automated wet processing systems, enabling gentle, cost effective wafer drying with lower particle counts.

Marangoni dryers enable high purity drying of semiconductor wafers during the computer chip manufacturing process. Modern chips for devices such as smartphones require ever smaller geometries with very low particle contamination. Their use has been limited because of the challenges of integration, and the high cost of N(2) (Nitrogen gas) needed for production. MEI's Genesis Xi dryer enables multistep oxide or ionic cleaning with integrated wafer drying; this eliminates the air interface, producing superior surface conditioning for semiconductor processing. MEI's Genesis series of integrated Marangoni dryers use significantly less N(2) and provide high drying performance in 7-20 minutes. "Our Genesis Marangoni dryers enable chemical oxide cleans before drying with no air interface and no damage to photoresist," says Product Marketing Manager Scott Tice. "We've achieved exceptional particle control, which is really meeting customer needs for improved yield."

The integrated Marangoni dryers are available immediately as an option in MEI's high performance fully automated "Evolution" wet processing systems and MEI's semi-auto "Revolution" batch wet processing systems.

About MEI Wet Processing Systems and Services

Founded in 1990 and based in Albany, Oregon, MEI Wet Processing Systems and Services LLC, is a wet processing equipment and services company serving semiconductor, MEMs, solar and high technology industries.  MEI Wet Processing is a subsidiary of MEI LLC of Oregon, with sales offices in the United States, Europe, China and Taiwan. MEI's specialties include patented solutions for wet processing applications, automated and semi-automated wet process systems and services; linear and rotary wet benches for the semiconductor and material processing industries; automated chemical delivery systems; and IDX advanced process control software. MEI has built its reputation on a commitment to outstanding customer service. www.meillc.com

For more information, contact:Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â

Ed JeanÂ

MEI Wet ProcessingÂ

541 704 2427Â