Urethane Foams feature reflective facings.

Press Release Summary:

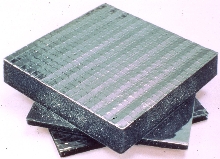

TUFCOTE® RM and SM urethane foams are designed for noise control applications where radiant heat may degrade acoustical materials. Aluminized polyester facings protect foam from soil and fluids. While SM facing is smooth, RM facing incorporates crisscrossed fiberglass filaments, which help to limit rips and tears if facing is punctured. Foams are available in rolls, sheets, or as custom die-cut parts in thicknesses ranging from 1/4 to 2 in.

TUFCOTE® RM and SM urethane foams are designed for noise control applications where radiant heat may degrade acoustical materials. Aluminized polyester facings protect foam from soil and fluids. While SM facing is smooth, RM facing incorporates crisscrossed fiberglass filaments, which help to limit rips and tears if facing is punctured. Foams are available in rolls, sheets, or as custom die-cut parts in thicknesses ranging from 1/4 to 2 in.Original Press Release:

Acoustical Foams' Shiny Facings Deflect Heat, Block Dirt

For noise control applications where radiant heat may degrade acoustical materials, E-A-R Specialty Composites offers TUFCOTE® RM and SM urethane foams, with reflective facings. The aluminized polyester facings protect the foam from soil and fluids. They also deflect radiant heat, such as that from a

motor, and help to control the temperature of the foam. TUFCOTE RM and SM foams are commonly used to line engine compartments and enclosures for motor-driven equipment, such as pumps and compressors.

While the SM facing is smooth, the RM facing incorporates criss-crossed fiberglass filaments, which help to limit rips and tears if the facing is punctured. Both facings are applied to TUFCOTE acoustical foam during E-A-R's proprietary thin sheet casting process, which casts the foam to thickness in continuous sheets. The highly cost-effective process also permits in-process bonding of the film facings, as well as pressure-sensitive adhesives and other backings.

TUFCOTE RM and SM foams are available in rolls, sheets or as custom die-cut parts, with or without peel-and-stick adhesives, and in thicknesses ranging from 1/4-inch to 2 inches.