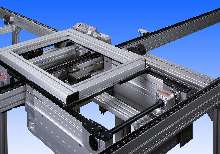

Transfer System can carry pallets up to 250 kg.

Press Release Summary:

The TS 4plus modular transfer system has low profile design for use in wide conveying applications. System includes steel chain guides with low-friction accumulation roller chain and polyethylene gliders to ensure quiet conveying and low wear. Shock absorbers reduce impact noise to <70 dB. Conveying speed can be doubled section by section using acceleration modules. Cushioned stops and stop gates with adjustable damping force and rebounce stop are available.

Original Press Release:

New Generation of The TS 4Plus Transfer System From Bosch Rexroth AG Offers Enhanced Economic Efficiency and Versatility

High economic efficiency due to low-priced modules is the main feature of the new generation of the TS 4plus, which can convey pallets that weigh up to 250 kg. The low profile design also means that this transfer system can be used for the widest variety of conveying applications.

Great attention was paid to creating a sturdy and durable design for all the new components in the Rexroth modular transfer system. For instance, the chain guides of the new BS 4 conveyor section are made of steel and the low-friction accumulation roller chain comes with steel support wheels. The compact BS 4 conveyor section can be used to set up segmented transport sections and short transverse sections. The WT 4 workpiece pallet is made of universal aluminum carrying plates with a choice of two thicknesses. WT 4/F workpiece pallets featuring a stable, open aluminum frame structure are optionally available. Both workpiece pallet types run on polyethylene gliders ensuring quiet conveying and low wear. In addition, shock absorbers reduce impact noise to less than 70 dB(A) - even when workpiece pallets are fully loaded.

For systems where cycle time is critical, the conveying speed can be doubled section by section using acceleration modules, which means that workpiece pallets are fed out at higher speeds from processing stations. The HQ 4 lift transverse unit is an additional component in the TS 4plus modular system. With its total height of just 300 millimeters, it is easy to create multi-level system layouts. The PE 4 positioning unit, which lifts the workpiece pallet about 5 millimeters above the conveying surface, also contributes to this system capability. Furthermore, cushioned stops and stop gates with progressively adjustable damping force, as well as a rebounce stop are available.

Bosch Rexroth AG, a one-hundred-percent owned subsidiary of Robert Bosch GmbH, achieved sales of 3.62 billion Euro in 2002 with approximately 25,500 employees. The company was formed in May 2001 by the merger of Bosch Automationstechnik and Mannesmann Rexroth and now combines under the brand name of Rexroth the range of products and services of the former brands of Bosch Automation, Brueninghaus Hydromatik, Indramat, Lohmann + Stolterfoht, Mecman, Refu, Rexroth Hydraulics and Star. Rexroth offers all relevant drive, control and motion technologies: from mechanics, hydraulics and pneumatics through to electronics as well as the associated services - and in around 80 countries worldwide.