Syringe Filling Systems offer consistent adhesive packaging.

Press Release Summary:

Series 8000BF syringe filling systems load 3cc to 55cc syringes without contamination, waste, or cleanup. Pneumatically operated systems use microprocessor circuitry, and make it possible for 1 worker to fill up to 500, 30cc syringes per hour with ±2% accuracy. Systems handle adhesive viscosities ranging from gel cyanoacrylates to thick sealants, and are designed for use with silicone-free syringes, pistons, and caps.

Series 8000BF syringe filling systems load 3cc to 55cc syringes without contamination, waste, or cleanup. Pneumatically operated systems use microprocessor circuitry, and make it possible for 1 worker to fill up to 500, 30cc syringes per hour with ±2% accuracy. Systems handle adhesive viscosities ranging from gel cyanoacrylates to thick sealants, and are designed for use with silicone-free syringes, pistons, and caps.Original Press Release:

New Syringe Filling Systems Offer Fast, Consistent Adhesive Packaging

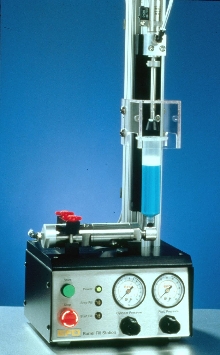

East Providence, RI USA -- EFD's new 8000BF Series syringe filling systems are a fast, cost-effective way to load 3cc to 55cc syringes without contamination, waste or cleanup. Combining a fast fill rate with microprocessor circuitry, these compact, pneumatically operated systems make it possible for a single worker to fill up to (500) 30cc syringes per hour with ±2% accuracy.

The 8000BF syringe fillers are versatile systems that handle a wide variety of adhesive viscosities, ranging from gel cyanoacrylates to thick sealants. Adhesive manufacturers, contract packagers and high-volume adhesive users will benefit from their speed, accuracy and cleanliness.

All 8000BF Series syringe fillers are designed for use with EFD's silicone-free syringes, pistons and caps. When used together, EFD equipment and packaging components form a complete system that gives adhesive packagers the ability to quickly and neatly fill every syringe with the correct amount of material, so the end user receives a clean, consistent product.

To load a syringe, the operator simply sets air pressure, adjusts a limit switch to the proper fill height, threads the syringe onto a fitting, and taps an electric foot pedal. By filling the syringe from the bottom up, waste and mess are eliminated and air pockets are greatly reduced.