Software assesses products before packing/installation.

Share:

Press Release Summary:

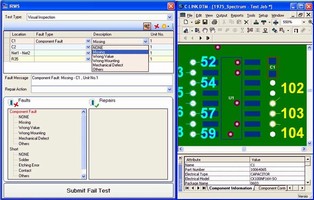

QMAN v5 quality management software captures fault messages logged by visual and diagnostic workstations as well as automatic test equipment. Functional test parameters can be entered and pass/fail test results can be written into quality management database. Data entry station IRWS (Inspection and Repair Work Station) offers textual description/graphical display of failures in layout/schematics display modules and enables collecting/managing/preparing of data in Microsoft SQL server database.

Original Press Release:

Digitaltest Launches the New Versatile QMAN Data Entry Station IRWS - First to be Seen at Electronica 2008, Munich/Booth A1.638

Stutensee, Germany - October 2008 - Digitaltest is launching the brand new, versatile QMAN data entry station IRWS (Inspection and Repair Work Station,) which is suitable for various tasks.

One of the main applications is the use for data entry at visual inspection workstations. A checklist can be provided which must be completed by the operator to confirm that the visual inspection has been carried out. The same would apply at functional test stations where it is often quite difficult to interface functional test results into quality management systems. The IRWS station provides highly flexible support where Functional test parameters can be entered and pass/fail test results can be written into the quality management database.

Besides these applications the new QMAN module can also be used to advantage at other points in the manufacturing process e.g. for packaging stations.

Before packing or installing an assembly, the serial number can be scanned at the IRWS station the software would check if all tests have been completed with a "pass". The assembly will not be released for packaging or installation until all necessary tests are confirmed as passed. If any operational step had been missed, the system could indicate which step and, where to re-insert the assembly.

The product can also be easily integrated with systems from other vendors and is available for immediate sale.

More about QMAN

QMAN Version 5 is the Quality management software for the MTS systems as well as other testers from other manufacturer. QMAN on-line facilities capture the fault messages logged by Visual and Diagnostic work stations, Automatic Test Equipment and other critical process areas. The basic idea is to offer the information required during the production process all the time and at every place. In addition, the repair data can be used data is used to generate trend alarms and statistical information for management to evaluate the quality of the production process.

QMAN 5 offers a comprehensive set of tools:

. Central storage and management of board data used for test and

repair

. Direct communication between test system and workstations (paperless

repair)

. Precise textual description and graphical display of failures in the

Layout and Schematics Display modules

. Collecting, managing, and preparing of failure data for quality

assurance in an Microsoft SQL server database.

. Minimization of the management efforts required at the connected

workstations, since all workstations have access to a central

database.

. Reduction of the repair times for faulty boards due to powerful

tools. The workstation has access to information like the description of

the current failure, the layout and schematics of the board, the parts

list and any repair actions for the board that have performed previously.

Entering the board identifier will show the corresponding test results

and failures. The identifier can be also used to show the matching layout

and schematics data.

. Statistical evaluation of failure data to make a statement about the

production quality and frequent failure sources.

. Automatic update of an archive database that keeps the information

of each passed board.

. Real time process control by continuously monitoring the quality of

the current production process and generating trend-alarms in case of

production problems.

. Flexible configuration of different workstations as diagnosis,

repair, maintenance, or management stations.

All QMAN modules provide a WindowsR based user interface which is easily comprehensible and thus reduces the training period even for semi-skilled repair operators to an absolute minimum. On-line help for the main modules will be provided.

About Digitaltest

Digitaltest GmbH, based in Germany, is a worldwide leader in advanced hardware and software testing solutions for electronics manufacturers. We are dedicated to perfecting the manufacture and testing of Printed Circuit Board Assemblies (PCBAs) for our global customers. For more information on our integrated solutions and our support and service organization around the world, please visit our enhanced web site at www.digitaltest.net.

www.digitaltest.net

Mark Harding

North American Sales Manager

US Digitaltest, Inc.

5046 Commercial Circle

Concord, CA 94520

email: mharding@digitaltest.net