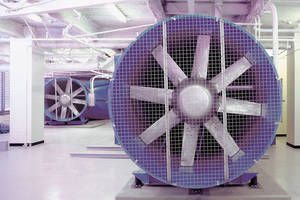

SKF® Solution for Upgrading Industrial Fans Combines Technologies for Increased Reliability

A new SKF® solution for upgrading industrial fans provides the capability to reduce bearing operating temperatures, increase fan reliability, and standardize an otherwise typically costly customized procedure. The upgrade combines optimized bearings, housings, and seals and an automatic circulating lubrication system to extend the service life of bearings and lubricant, reduce fan maintenance, and contribute to sustainability goals.

The fan upgrade focuses on reducing potentially high bearing operating temperatures, which can lead to bearing failure, shortened life of bearing lubrication, unplanned fan downtime, and production losses. The SKF solution enlists a variety of temperature-reducing components to reduce the risks.

Every upgrade is based on an initial assessment of fan problems followed by interrelated recommendations for the fix.

Elements include a circulating oil lubrication unit to reduce operating temperatures by removing heat; a self-aligning bearing system generating less friction (and less heat); several types of specially designed bearing housings and seals to help mitigate temperature issues; and a condition monitoring system to deliver early warning of potential bearing failure.

The fan upgrade offers a comprehensive and cost-effective solution grounded in the growing toolbox of SKF technologies.

Contact

SKF USA Inc.,

890 Forty Foot Road, Kulpsville, PA 19443

Phone: 800-440-4SKF

E-mail: skfusainfo@skf.com

Web site: www.skfusa.com

PR CONTACT:

Wendy Earle

267-436-6723