Single Needle Valve Gate Nozzle offers all-in-one construction.

Share:

Press Release Summary:

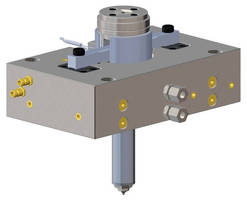

Designed for use with nozzles of TechniShot Z33/… series, ready-to-install SNV-06/-12 feature hydraulic or pneumatic drive, melt detection, and flanged-on nozzle. Needle diameters of 2–6 mm and needle strokes of 8–12 mm minimize pressure losses, while melt guidance enables results achieved with single-cavity mould to be directly transposed to multi-cavity applications. With optimized temperature distribution, heating concept allows application versatility for engineering plastics.

Original Press Release:

New Single Needle Valve Gate Nozzle - Ready-to-install, All-In-One Solution

Needle valve gate nozzles located centrally in the mould always constitute a particular challenge, since the central melt feed means that the drive cylinder cannot be positioned axially behind the needle.

The new HASCO single needle valve gate nozzle SNV-06, SNV-12, with the corresponding melt deflection, is now available as a ready-to-install, all-in-one unit with either hydraulic or pneumatic drive, and includes a flanged-on nozzle. The use of standardised components and interchangeable parts, as well as the identical fitting space required for the hydraulic and pneumatic versions, make the unit particularly service-friendly.

The single needle valve gate nozzle is designed for use with nozzles of the TechniShot Z33/… series. Needle diameters of 2 to 6 mm and needle strokes of 8 to 12 mm ensure low pressure losses. Melt guidance similar to that in multi-cavity distributor systems means that results achieved with a single-cavity mould can be directly transposed to multi-cavity applications. The new heating concept with improved temperature distribution opens up a wider field of application for engineering plastics too. A uniform temperature profile is always ensured right through to the gate.

Customers benefit from extremely simple installation and maintenance in the mould. This then keeps the installation and process risk to a minimum, as well as the time taken for building a mould.

contact:

Hasco Hasenclever GmbH + Co KG- Lüdenscheid

Römerweg 4

58513 Lüdenscheid

Germany

Phone: +49 2351 957-0

Fax: +49 2351 957-237

Mail: info@hasco.com

Order-E-Mail: order.de@hasco.com