Shaft Grounding Brush protects AC motor bearings.

Press Release Summary:

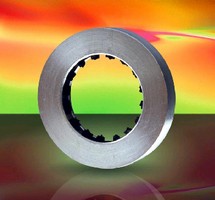

Available in sizes to fit NEMA AC motors ranging from 1-1,500 hp with shaft diameters from 0.311-6.020 in., AEGIS SGR(TM) Conductive MicroFiber Brush safely channels harmful shaft currents to ground. It is unaffected by dirt, grease, or other contaminants. Conductive microfibers work with virtually no friction and last life of motor. Brush is installed by sliding ring over either end of motor shaft and locking it in place with screw-on mounting brackets.

Original Press Release:

Conductive Microfiber Shaft Grounding Brush Protects AC Motor Bearings

MECHANIC FALLS, ME - The new AEGIS SGR(TM) shaft grounding brush from Electro Static Technology prevents electrical damage to AC motor bearings and extends motor life by safely channeling harmful shaft currents to ground. Conductive microfibers inside the AEGIS SGR provide the path of least resistance for shaft currents to discharge to the motor frame. Maintenance-free, the SGR is unaffected by dirt, grease, or other contaminants and provides the longest-lasting protection available.

When variable frequency drives (VFDs) are used to control AC motors, currents are induced on the motor shaft. These currents build up until they are strong enough to discharge through the bearings, causing frosting, pitting, fusion craters, and fluting. Over time, these discharges can lead to bearing failure and motor failure. The AEGIS SGR provides an alternate path to ground for these shaft currents, preventing bearing damage and extending motor life.

The patent-pending AEGIS SGR Conductive MicroFiber(TM) Brush is easily installed by sliding the ring over either end of the motor shaft and locking it in place with simple screw-on mounting brackets. Because no machining is required, the SGR can be installed in minutes - even in the field.

Unlike conventional shaft grounding brushes, which wear out quickly and lose their effectiveness, the AEGIS SGR's conductive microfibers work with virtually no friction and no wear and last for the life of the motor. There are no RPM limitations on the operation of the motor.

The SGR is available in standard sizes to fit NEMA AC motors ranging from 1 to 1500 HP with shaft diameters from 0.311" to 6.020" (8 mm to 153 mm). Larger sizes are available for shafts with diameters greater than 6".

Electro Static Technology is the global leader in the elimination and/or mitigation of induced electrical charges on rotating and moving surfaces. Other products include FLX-P(TM) flexible peel-and-stick passive static eliminators for printers, copiers, and other imaging devices. Electro Static Technology is a division of Illinois Tool Works (ITW), a $10 billion multinational conglomerate operating in 44 countries.

For more information, contact: Adam Willwerth, Sales and Marketing Manager, Electro Static Technology, 31 Winterbrook Road, Mechanic Falls, ME 04256, Toll-Free: 1-866-738-1857, TEL: (207) 998-3493, FAX: (207) 998-5143, sales@est-aegis.com, www.est-aegis.com.