Rugged Safety Light Curtain is expandable.

Press Release Summary:

Shadow® 8 can guard multiple sides of machine with only one pair of cables connected to clutch/brake control or to optional Shadow 8 Control. Main heads can be used as standalone light curtain, or users can connect 1-3 pairs of extension heads in series with main unit. Programmable fixed blanking window allows fixtures like conveyors or worktables to remain in sensing field without triggering machine stop. Light curtain is OSHA 1910.217, ANSI B11.1, ANSI B11.19, CSA Z142, and CSA Z432 compliant.

Original Press Release:

Honeywell's New Shadow 8 Light Curtains Enable Greater Safety for Metal Stamping and Forming

Easy-to-Use Product Can Safeguard Multiple Sides of a Machine with One Control

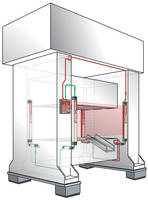

ACTON, Massachusetts, April 14, 2009 - Honeywell (NYSE:HON) Wintriss today introduced Shadow® 8, a slim, rugged, expandable safety light curtain for demanding industrial manufacturing applications like metal stamping and forming. The latest product in the Shadow light curtain series can be used to guard multiple sides of a machine with only one pair of cables connected to a Wintriss Clutch/Brake Control (WPC) or to an optional Shadow 8 Control.

"Our customers have been asking for a new light curtain that would provide additional flexibility and reduce hardware costs," said Ashok Bhide, marketing manager, Honeywell Wintriss. "Shadow 8 light curtains are designed to allow customers to add a second, third, or even fourth pair of optic heads to the same control. They also are easier to install and use, all of which helps to make our customers' jobs easier."

The basic Shadow 8 system includes a main pair of light curtains and cables for wiring the curtains to a WPC or to the optional Shadow 8 Control. The main heads can be used as a standalone light curtain. Alternatively, users can connect one to three pairs of extension heads in series with the main unit. Extension heads can be added at any time. Quick-disconnect fittings on the pigtails are easily attached to the main unit or to another extension. Interconnect cables are also available for protection of larger areas.

Shadow 8 standard features include a programmable fixed blanking window that allows fixtures such as conveyors or worktables to remain in the sensing field without triggering a machine stop. Users simply place a fixed object between the transmitter and the receiver and simultaneously turn two key-lock switches on the WPC or optional Shadow 8 Control. Shadow 8 senses the presence of the object and disables the obstructed beams. Users can also set a one-beam floating blanking window to allow small objects, such as air-ejected parts, to pass through the light curtain in a random pattern without interrupting operation. Floating and fixed blanking can be active at the same time.

Shadow 8 complies with OSHA 1910.217, ANSI B11.1, ANSI B11.19, CSA Z142, and CSA Z432. Shadow 8 has undergone multiple, independent compliance and testing and has achieved the following certifications: Underwriters Laboratories (NRTL/C) to CAN/CSA 22.2 No. 14 and CAN/CSA 22.2 No. 0.8; TÃœV to Category 4 CE/IEC 61496-1, CE/IEC 61496-2; and SIL 3 per EN 61508. The optic heads and optional control are both rated IP65.

For more information about Shadow 8 features, as well as information about other Honeywell solutions that can improve business performance, visit www.wintriss.com.

Honeywell Wintriss, a part of the Honeywell Process Solutions business, provides a broad portfolio of automation, safety and real-time data collection products to the metal stamping and forming industry. The product range includes laser guarding systems for hydraulic press-brakes, light curtains, clutch/brake controls, die protection systems, load analyzers, in-die quality control systems and production reporting software. Additional information about Honeywell Wintriss is available at www.wintriss.com.

Honeywell Process Solutions is a part of Honeywell's Automation and Control Solutions group that provides product and service solutions that improve efficiency and profitability, support regulatory compliance, and maintain safe, comfortable environments in homes, buildings and industry. For more information about Honeywell Process Solutions, visit www.honeywell.com/ps.

Honeywell International is a $37 billion diversified technology and manufacturing leader, serving customers worldwide with aerospace products and services; control technologies for buildings, homes and industry; automotive products; turbochargers; and specialty materials. Based in Morris Township, N.J., Honeywell's shares are traded on the New York, London and Chicago Stock Exchanges. For additional information, please visit www.honeywell.com.