ROHM's H Bridge Motor Driver Achieves Lower Power Consumption by Converting Conventional DC Voltage Variable Drive to Higher-efficiency PWM Drive with Same DC Voltage Input

Extensive lineup for wide range of brush motors and protective features that heighten reliability

Motors have been a driving force behind industry and our daily lives for as long as anyone can remember. Over a century has passed since the first Japanese-made motor was produced, and the range of motors' applications is still expanding today.

Even among compact motors, brush motors are notable for their small size, light weight, high efficiency, low price, ease of control, low-voltage drive, and simple structure that make them suitable for general-purpose applications in a broad spectrum of devices.

ROHM regards the brush motor market as important and has focused much effort on development of H bridge motor drivers for brush motors, building an extensive product lineup and addressing the issues of boosting efficiency and lowering power consumption, which are common needs among all electric and electronic devices.

The H bridge motor driver series that we focus on here is equipped with the same DC voltage drive as its predecessors, but with the internal mechanism converted to PWM drive to achieve higher efficiency and lower power consumption.

Review of H bridge motor control

The H bridge circuit was devised to perform four actions: the motor's forward rotation, reverse rotation, stopping, and standby (idling). The name "H bridge" is derived from its shape, which resembles the letter H.

Switches

The actions are performed in simple manner with four switches that switch the brush motor's two terminals among (1) forward rotation with positive bias (though it is not determined which direction is positive), (2) reverse rotation with negative bias, (3) stopping with a short circuit, and (4) standby (idling) in release mode.

Although we used the word "switch," in fact transistors are used, which turn on and off in response to a control signal and supply the necessary current to the motor drive. With current passing through transistors, it is necessary to take transistor power loss into account.

Bipolar transistors are used in many cases due to withstand voltage and other considerations, but the saturation voltage (= loss voltage) of VCE is undeniably high compared to loss (RON~IDS) when MOSFETs are used.

Meanwhile, when MOSFETs are used, there are concerns in that Nch MOSFETs should be used on both the high side and the low side, as in recent synchronous rectification type DC/DC converters, in the pursuit of low ON resistance (RON), but voltage higher than VCC is required in order to drive the high-side Nch MOSFET (in most cases a circuit to boost VCC is added).

With a Pch/Nch configuration, voltage boosting is not required, but there is a trade-off in that the RON of a Pch MOSFET is high compared to that of Nch, or with low RON the cost goes up.

Drive method

For motor drive and control, there is a DC bias method and a PWM (pulse width modulation) method.

The descriptions below assume the use of a driver IC, but in the case of DC voltage drive, DC voltage known as VREF is generally used for motor drive with the IC's power supply VCC reduced.

It is basically the same as a linear regulator, and there are disadvantages in terms of efficiency and heat generation: all the power that is voltage differential between VCC(VIN) and VREF(VOUT) multiplied by drive current will become a loss.

Meanwhile, PWM can be thought of as a switching regulator. It basically modulates the time (pulse width) of switching (on/off) VCC voltage and drives the motor with the average power obtained, performing efficiently because it extracts no more power than necessary.

PWM is also generally said to have advantages in terms of responsiveness and control precision. The concerns that exist are: where to obtain the PWM signal from, and the cost and space requirements of the components.

*With PWM drive, efficiency is high because only the required amount of power is drawn from the power supply VCC.

By contrast, when generating DC voltage for DC drive using the linear regulator method, all VCC is used to obtain the required voltage and the leftover portion is discarded (lost), so in general terms efficiency is poor.

*1: Theoretical value. In practice, there is no such thing as 100% efficiency, but higher efficiency than with the linear regulator method can be expected.

High-efficiency PWM drive with DC input: Taking on the challenges of H Bridge Motor Drivers

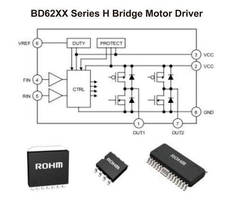

The ROHM BD62XX Series are H Bridge Motor Drivers that address the challenges described above. The features and advantages of the series are outlined below.

Features and Advantages

EPWM drive with DC voltage input Ë Can be used in the same manner as conventional DC bias, with high efficiency and no need for external PWM

EPWM input possible as well Ë High degree of design flexibility

EPch/Nch MOSFET configuration output stage Ë Loss reduced compared to bipolar transistor, no voltage boost necessary

EBuilt-in through current prevention circuit Ë Prevents upper and lower MOSFETs from turning on at the same time and causing massive current to flow

EEquipped with 4 protective circuits Ë Improves safety and reliability of application devices

The extremely unique point is the ability to use "PWM drive with DC voltage input". The mechanism is: when DC voltage is applied to the VREF pin, as with conventional DC bias drive, internal conversion to the PWM signal with the VREF:VCC ratio is performed and the signal is output by PWM drive. This is an extremely useful mechanism for users who "want to change from DC drive to PWM to boost efficiency, but have no PWM signal source."

Direct PWM input is possible as well, enabling a high degree of design flexibility, for example when utilizing the advantages of the BD62XX Series while building on existing circuitry with PWM specifications.

*Built-in VREF-PWM conversion circuit enables PWM drive with DC voltage.

Select operation with FIN and RIN logic inputs. The PWM duty ratio is VREF/VCC.

Example: On 75%/Off 25% when VCC=5V and VREF=3.75V

It is also possible to drive with PWM input directly into FIN and RIN inputs.

An output stage transistor (switch) with Pch/Nch MOSFET configuration, like a configuration with only Nch, does not require a voltage boost, and enables reduction in the number of components.

The preceding section mentioned the RON of Pch MOSFET, and with the BD62XX Series, the data sheet guarantees the total RON combining the high-side Pch RON and the low-side Nch RON. For example, with the 1A grade, a maximum total resistance of 1.5 ohms is guaranteed. With the 2A grade, the corresponding figure is 1.0 ohms. These values are quite small when IC functions are considered, though not as small as individual MOSFETs.

Full range of protective features that heighten reliability

As a matter of fact, it is possible to make the H Bridge Motor Driver circuit with a discrete configuration, but when doing so it is extremely difficult to equip it with protective features. Because it is necessary to combine, for example, MCUs with analog front end that performs processing with feedback of measurement results for temperature, etc. as well as current and voltage, such a configuration requires a greater number of more complex parts than a driver circuit. With an IC, however, all the circuitry can be loaded in one unit, which is extremely advantageous.

The unit is equipped with the following protective features.

EThrough-current prevention circuit (refer to illustration at right regarding through-current)

ETSD (Thermal Shut Down) circuit

EOCP (Over Current Protection) circuit

EOVP (Over Voltage Protection) circuit

EUVLO (Under Voltage Lock Out) circuit

These features are all important in terms of heightening the safety and reliability of application devices.

*When changing switch settings, if both upper and lower sides are "on" at the same time, it causes ground fault status to occur.

Extensive lineup to support wide range of brush motors

The BD62XX Series consists of a matrix of voltage, channel number, and output current options. There are also variations available such as a large current series and high-speed drive series, ensuring suitability for a diverse range of brush motors and applications. The list below is not complete but is an excerpt of the most popular options. Please follow the link to related materials for details.

H Bridge Motor Driver: BD62XX Series

H Bridge Motor Driver: Large Current Series

H Bridge Motor Driver: High-Speed Drive Series

Note 1:Â The product name suffix is a code indicating the package type. F: SOP8, FV: SSOP-B16, HFP: HRP7, FP: HSOP25, FM: HSOP-M28, MUV: VQFN

Note 2: The Large Current Series and High-Speed Drive Series do not have PWM drive (internal VREF-PWM conversion) with DC input voltage

Summary

Thus far we have examined the features of the ROHM H Bridge Motor Driver BD62XX Series. Simply put, it is a "PWM-controlled H bridge motor driver with built-in MOSFET switch to boost efficiency and decrease power consumption," but it is distinguished by the capability to have PWM drive with DC voltage input, which represents the realization of an extremely user-oriented concept: achieving an alternative to existing DC bias control circuitry without adding PWM circuitry. There are more developments to look forward to in the future, as ROHM continues to enrich and expand this series.