REDBUD LABS STRâ„¢ Microfluidic Chip Enables 1000x Faster Sample Prep for On-cartridge Magnetic Bead Assay

Cartridge-ready™ STR Chip facilitates lower-risk development of point-of-care diagnostics by leveraging proven magnetic bead sample prep chemistry

Research Triangle Park, N.C., Dec. 19, 2019 /PRNewswire/ -- Redbud Labs announced today new results that expand the menu of functional chemistries for its sample preparation chip, STR™ ("sorter"). The new protocol outperformed not only the cartridge-based alternative, but even the benchtop microbead assay. In the new study, STR captured 94% of targets in 5 minutes, compared with 81% for the benchtop assay, and just 9% for an on-cartridge method without STR. STR also enabled 1,000x faster performance, achieving in just one minute the capture rate of a conventional on-cartridge method in an overnight incubation.

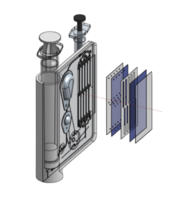

These results are possible thanks to an innovative new conjugation method. STR is a fast, cartridge-ready microfluidic component for sample preparation. It is powered by Redbud Posts™ that have been chemically modified with a specific probe, such as an antibody, oligomer nucleotide, or a generic binding moiety such as neutravidin. In the new protocol, the conjugation is achieved by decorating a Redbud Post array with magnetic microbeads. This new method joins Redbud's original conjugation method, in which the Redbud Posts' base elastomer is directly modified with the binding chemistry. The new method effectively makes STR backwards-compatible with the vast library of established magnetic bead chemistries.

"At the bench, magnetic beads are adaptable and reliable. In sample-to-answer cartridges, they perform poorly," said Richard Spero, Redbud's CEO. "With this new protocol, we've shown how STR can seamlessly port a benchtop magnetic bead assay to a microfluidic cartridge, and even boost assay performance in the process. Now system developers can know that beads will perform as well or better on-cartridge as they did at the bench, reducing risk in their R&D plan. Our customers are already evaluating this new method, and we can't wait to see how STR can boost their assay performance and accelerate their product development timelines."

To establish the performance of the new method, Redbud's scientists first quantified the extent to which a magnetic bead protocol degrades when transferred to a microfluidic chamber. Then the assay was performed in a STR chip where the beads were magnetically coupled to a Redbud Post™ array, which was actuated during incubation to agitate the sample. These results were compared to a conventional benchtop protocol in which the magnetic beads were incubated in a PCR tube on a rotator.

Jay Fisher, Redbud's Vice President of R&D, said, "The increased surface area in the STR chip, together with the actuation of the Redbud Posts, maximizes the transport of the targets to the binding surface. In this new protocol, the binding surface is provided by the same magnetic beads we used at the bench, leveraging decades of industry investment in bead chemistry. This combination enabled STR to exceed the performance of the benchtop magnetic bead methods. With the enormous back catalogue of magnetic beads, the opportunities using this method are endless."

The full application note was released today at redbudlabs.com/str/.

About Redbud

Redbud Labs®, headquartered in Research Triangle Park, North Carolina, manufacturers cartridge-ready™ microfluidic components for life science industry. MXR™, the world's fastest, most adaptable microfluidic mixing chip, and STR™, the first cartridge-ready sample prep solution, address some of the industry's toughest microscale fluidic challenges. Redbud technologies have broad application across a variety of segments including basic research, drug discovery and development, biomanufacturing, point-of-care molecular diagnostics, sequencing, and applied markets. Industry partners seek Redbud's proprietary Redbud Post™ technology, component design expertise and deep scientific know-how to advance their own next generation products. Rebudlabs.com

For Further Information Contact:

Kathryn Lawrence

VP Business Development

Redbud Labs

+1 919-537-9753 x97

lawrence@redbudlabs.com

Source Redbud Labs, Inc.

Web Site: https://www.redbudlabs.com