Packing System utilizes load cells and PLC controllers.

Press Release Summary:

Force Flow Packer utilizes fluidization to fill bags at rates up to 5 bags per minute by supporting particles in upward airstream. During operation, powder is fluidized forcing product through filling tube. Unit is designed for 24 hour/day operation with low maintenance and minimized number of moving parts. Force Flow Packer will fill most types of paper or plastic valve bags, and 1 operator can control packing line of up to 4 machines.

Force Flow Packer utilizes fluidization to fill bags at rates up to 5 bags per minute by supporting particles in upward airstream. During operation, powder is fluidized forcing product through filling tube. Unit is designed for 24 hour/day operation with low maintenance and minimized number of moving parts. Force Flow Packer will fill most types of paper or plastic valve bags, and 1 operator can control packing line of up to 4 machines.Original Press Release:

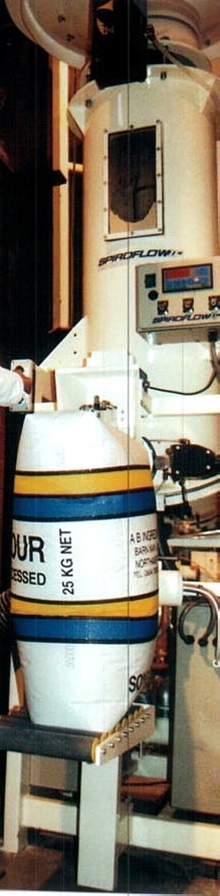

Force Flow Bag Packing System For Increased Efficiency

Charlotte, North Carolina---Spiroflow Systems has recently introduced the new Force Flow Bag Packing system to its equipment line of small bag packing products.

The Force Flow Packer utilizes fluidization to rapidly fill bags by supporting the particles in an upward airstream. During operation, the powder is fluidized forcing the product through a filling tube. The unit is designed for 24 hour/day operation with low maintenance and a minimum of moving parts.

The Force Flow Packer will fill most types of paper or plastic valve bags at up to five bags per minute. One operator can control a packing line of up to four machines.

The packer incorporates load cells for accurate packing and PLC controllers for a turnkey solution to most bag packing needs.

A full variety of options are also available including bulk storage hoppers, bag applicators, feed systems and take-off conveyors for complete flexibility.