New VarioDuct from FabricAir is Designed for 1,000 to 1,600-fpm

Press Release Summary:

- Provides high heating and cooling capacity

- Available in diameters ranging from 16 to 32-inch diameter

- Can be specified automatic with an onboard 120V, 24V or 230V motorized actuator

Original Press Release:

FabricAir® VarioDuct Provides Perfect Uniform Heating and Cooling from the Same Fabric Duct

VarioDuct’s motorized damper actuator automatically switches a duct run between bottom or top air dispersion for uniform heating and cooling temperature gradients.

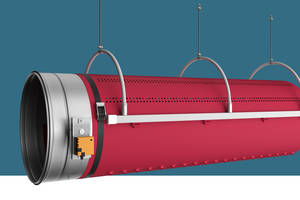

FabricAir®, Lawrenceville, Ga., a leading manufacturer of fabric HVAC duct and accessories, has introduced the VarioDuct™, a highly engineered solution for most commercial building applications that provides both uniform heating and cooling out of the same ceiling-hung fabric duct.

All ceiling-hung ducts are conducive to air conditioning since cool air descends through the occupied zone. However, VarioDuct’s unique design overcomes the natural convection characteristics of heated air to provide uniform cooling and heating temperature gradients from the same straight run of duct. Numerous efficiency studies have proven uniform air dispersion results in reduced mechanical equipment runtimes. Consequently, VarioDuct provides unprecedented air comfort and saves up to 25-percent in energy costs vs traditional metal systems.

This heating and cooling uniformity from the same duct run is made possible with a full length internal membrane that’s positioned via a mechanized damper to disperse either warm air through its bottom hemisphere or cool air through its top hemisphere. When the membrane is positioned to block the duct’s top hemisphere vents during heating mode, the VarioDuct’s bottom hemisphere’s precisely engineered OriFlow™ orifices, NozzFlow™ nozzles or JetFlow™ jets capably disperse warm air down to the occupied level regardless of ceiling height. The opposite occurs for cooling mode as the membrane is positioned to block the bottom hemisphere’s vents to disperse cold air through the top hemisphere’s SonicFlow™ or MicroFlow™ vents promoting a natural descent to the occupied zone. A minimum static pressure of 0.2-iwg (50-pa.) is required to hold the membrane in place during heating mode.

The mechanized damper/hoop that positions the membrane is part of a flanged, 14-inch-long (355-mm) galvanized steel inlet collar assembly. The hoop can be switched between heating and cooling modes via a manually-operated hand crank, or automatically via a motorized actuator activated by a thermostat or building automation system (BAS).

VarioDuct can be ordered in FabricAir’s permeable or non-permeable Combi or Trevira fabric, both which are applicable to conventional commercial and mission critical applications. Combi and Trevira are UL and CSA-listed and are accepted by all building codes in compliance with NFPA 90A-2018.

VarioDuct is available in any length and in diameters ranging from 16 to 32-inch-diameter (400 to 800-mm). It can be hung with a variety of FabricAir suspension systems depending on project aesthetics. All of FabricAir’s unlimited color palette hues and graphics, such as patterns and custom logo inscriptions, are available for VarioDuct.

Other VarioDuct features are:

- Membrane is made of same material and color as the duct and blocks vents with minimal leakage;

- Damper/hoop assembly is lighter, yet sturdier than competitors;

- The damper/hoop, which uses a longer-lasting square shaft, can be specified automatic with an onboard 120V, 24V or 230V motorized actuator by Belimo, Danbury, Conn.;

- Can be value-engineered by substituting the motorized damper/hoop assembly with a manually-operated crank for switching between heating and cooling;

- Designed for 1,000 to 1,600-fpm;

- 5-year warranty.

For more information on the VarioDuct or other FabricAir duct and accessories, please visit www.fabricair.com; email sales-US@fabricair.com or contact customer and technical support departments at (502) 493-2210.

About FabricAir: FabricAir designs and produces custom air dispersion & air distribution solutions for a wide range of applications. In 1973 we installed the world’s first fabric ducting system, which heralded a whole new way of thinking within HVAC and indoor climate. We continue to be at the forefront of innovation and proudly deliver superior air dispersion across the globe through sales companies and a substantial distributor network. Our experienced engineers ensure ideal air flow regardless of project complexity. We are headquartered in Denmark and all systems are produced to measure at our facility in Lithuania. For more information on the VarioDuct or other FabricAir duct and accessories, please visit www.fabricair.com; or contact customer and technical support departments at sales-US@fabricair.com or by calling (502) 493-2210.

Contact: Charles J. Justice—National Sales Mgr.

FabricAir

(502) 493-2210

chj@fabricair.com

or John Parris Frantz

J.P.F. Communications

(773) 871-2600

john@jpfcomm.com