New Two-Collet Chuck Delivers Speed up to 10,000 rpm with 1:1 Ratio

Share:

Press Release Summary:

- Features 1,000 psi or 70 bar internal coolant

- Provides repeatability within five microns

- Available in horizontal type 90-degree radial holders and vertical type straight off-set axial holders

Original Press Release:

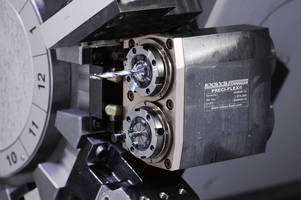

EXSYS Two-Collet Chuck Doubles Turret Station Capability

San Aantonio, Fla., June 17, 2019 – As a recent addition to its EPPINGER PRECI-FLEX® modular tooling system, EXSYS Tool, Inc., offers a revolutionary two-collet chuck that doubles the machining capability of one turning machine tool turret station. Designed for Mazak QUICK TURN and QTU Series turning centers with optional high-speed drive motors, Y-axis functionality and standard BMT turrets, the double-collet chuck can deliver speeds up to 10,000 rpm with a 1:1 ratio and 20 N-m of torque and features 1,000 psi or 70 bar internal coolant. In addition, 12,000 rpm live tool holders with a 1:1 ratio also are available.

With the double-collet chuck, shops can switch between fixed and rotary base holders with quick changeovers in one station on the machine turret, and mount any combination of two collets, endmill holders, expanding collet chucks and shrink fit tooling on a single base holder. For instance, a tap-and-drill or spot-and-drill combination becomes easy to set up for maximized equipment capability.

Available in Horizontal (H) type 90-degree radial holders and Vertical (V) type straight off-set axial holders, the PRECI-FLEX double-collet chuck provides repeatability within five microns. The tooling system features an EXSYS/EPPINGER Compensating Clutch with a floating coupling between turret drive motor tangs and toolholders that automatically compensates for misalignment. The resulting high precision reduces vibration and tool chatter for longer tool life and better surface finishes.

Manufactured by EPPINGER, the PRECI-FLEX modular system incorporates a conical and flat face planar interface that accepts either an adapter or a standard ER collet. The system offers unmatched flexibility, precision and cost savings, with an interface based on a well-known, universally used ER collet pocket configuration. The short, compact design with monoblock housing assures maximum torque transmission and rigidity, resulting in increased machining accuracy and improved productivity.

About EXSYS Tool, Inc.

Founded in 1987, EXSYS Tool, Inc. is the exclusive importer of German-made EPPINGER solutions, including high-precision live and fixed toolholders for CNC turning centers, modular adapter systems for quick lathe tooling changeovers and gear box solutions for a wide range of applications. With headquarters near Tampa, Fla., and support offices in California, Canada and Mexico; EXSYS offers a variety of different toolholders, gold-standard tooling repair and applications expertise to manufacturers throughout North America. For more information, please contact EXSYS Tool, Inc. at sleitch@exsys-tool.com or visit www.exsys-tool.com.

Media Contact:

dgs Marketing Engineers®

Chuck Bates

Director of Public Relations

317.813.2230

bates@dgsmarketing.com