New Tape Technologies Enhance Automotive Assembly

As future vehicle designs become more advanced, OEMs and auto manufacturers need to look beyond conventional methods of utilizing mechanical fixation or primers to bond to automotive surfaces.

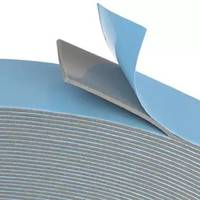

New tape technologies combine functionality and ease of use to secure attachment of protective trims, decorative trims as well as functional and small parts to the car body, door frame, tailgate or trunk. And, different tapes are available to best accommodate the size and type of the part that needs attaching, the location of the attachment (interior or exterior of the vehicle) and the type of surface it needs to be attached to.

Exploring Benefits of Key Norbond® Products

Our Norbond Z2000 Acrylic Tape Series is formulated to ensure durable, long-lasting adhesion for automotive exterior bonding on complex surfaces. Specifically, Norbond Z2000 offers outstanding viscoelastic and adhesion properties with short-term adhesion build. It boasts excellent adhesion to automotive paint systems, as well as Medium Surface Energy (MSE) plastics such as ABS and ASA. The bonding properties to other substrates that resist adhesion can also be improved with Norbond Adhesion Promoters.

However, now more than ever, OEMs are looking for solutions that make automotive assembly faster, save money and have better impact on workers’ health and the environment. This is where Norbond Z3100 Series becomes worth considering. This Series combines all the advantages of primerless bonding in one adhesive tape. It is designed for superior attachment of Low Surface Energy (LSE) substrates (i.e. PP-EPDM) to OEM clear coats and can fulfill challenging specifications like GMW15201.

Utilization of this tape can eliminate a full step in the automotive assembly process, as it doesn’t require pre-treatment of surfaces with adhesion promoters. This can accelerate the whole process while saving money, minimizing purchasing logistics and simplifying storing efforts.

Product Spotlight: Exploring Key Features, Benefits & Applications

Undoubtedly, Norbond Z3100 will be a key player in eliminating the need for primer in tape applications, offering a healthier and more simplified process with no sacrifice to performance. Characterized by its excellent adhesion of LSE plastics, such as PP-EPDM, to automotive paint systems or MSE plastics, such as ABS and ASA, Z3100 is a premier choice in applications including body side molding, wheel flares, rocker panels and spoilers. The Z3100 Series is specifically designed to provide the following features:

- Excellent primerless adhesion to LSE plastics on the non-liner side (NLS)

- Strong adhesion to OEM clear coats and MSE plastics on the liner side (LS)

- Engineered core that yields cohesive foam split across a range of OEM exposure conditions

- Superior peel strength with enhanced short-term adhesion build

- Reliable static holding power at temperatures up to 80°C

- High resistance to humidity and aging conditions

Connect with us today to learn more about this specific product, see how it compares with other products from our portfolio to determine your specific application needs. Our team has the know-how and global expertise to help you select the right tape to meet your demanding transportation application requirements.