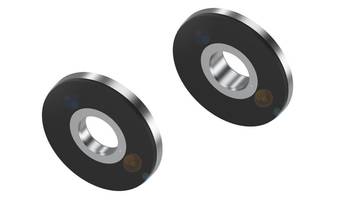

New Magnetic Discs from Balluff Deliver High Precision in Small Form Factor

Press Release Summary:

- Available in 3 mm. and up to 70 mm. inside diameters

- Offer reliable, non-contact and wear free measuring

- Ideal for use with absolute rotary magnetic encoders

Original Press Release:

New Compact Magnetic Discs from Balluff Offer Simple Integration

Small Form Factor Delivers High Precision for Tight Spaces

Florence, Kentucky (June 19, 2020) — Balluff’s new magnetic discs for use with absolute rotary magnetic encoders deliver high precision in an incredibly small form factor. That allows for use in tight spaces. They offer reliable, non-contact and wear free measuring.

Balluff offers a diverse portfolio of standardized flat and hub-shaped discs to match a variety of configurations. Inside diameters as small as 3 mm and up to 70 mm are available. Mechanical modifications can be created to meet specific application requirements.

Whether used with a complete system with sensor and electronics or integrated into a company’s electronics with the IC-MU encoder chip, this wide range of compact magnetic discs leaves nothing to be desired when it comes to mechanical integration and accuracy.

Key features:

- Non-contact and wear-free measuring principle

- Generous distance between sensor and disc

- Space-saving compact form factor

- Various codings available (16/15, 31/31, 64/63)

- Customized mechanical adjustment possible

Learn more at: www.balluff.com

About Balluff Inc.

Balluff Inc. is the U.S. subsidiary of Balluff GmbH, Neuhausen, Germany. Balluff is a leading supplier of networked IO-Link control system architectures that unlock the potential of the IIoT and Industry 4.0. Balluff offers a wide range of intelligent IO-Link and industrial Ethernet sensors in a variety of technologies including inductive, photoelectric, capacitive, and magnetic as well as magnetostrictive linear position sensors, magnetic tape linear encoders, industrial RFID systems, and industrial vision systems. Balluff provides cost-saving, process-enhancing solutions to machine builders and manufacturers to control, regulate, automate, assemble, position, and monitor manufacturing, assembly, and packaging sequences. Industries served include: automotive, packaging, food processing, beverages, tire, primary metals, conventional and alternative energy, semiconductor, plastics, and fluid power.