New Flashcell Load Cell Weighs Products at Speed of up to 800ppm

Press Release Summary:

- Fast product process and reduce product giveaway through improved weighing precision

- New T60 Integrated 360 Series provides serialization and aggregation of bottles and vials

- Reads and verify small product or serialization codes printed directly onto the bottle or applied labels

Original Press Release:

METTLER TOLEDO Introduces New Inspection Systems at Pack Expo Las Vegas 2021

July 27, 2021 -- METTLER TOLEDO Product Inspection introduces several new technologies in booth C-1814 at Pack Expo, being held at the Las Vegas Convention Center, September 27 -- 29, 2021.

The company’s metal detectors, checkweighers, machine vision systems, x-ray inspection systems and Track & Trace solutions will be demonstrated in areas for free-flowing and bulk products, packaged products, pharmaceutical products, rigid containers, pumped food products and unwrapped and unpackaged products. Among these inspection systems, two new metal detectors for wet and dry environments and an x-ray system for high-speed confectionary lines will be demonstrated.

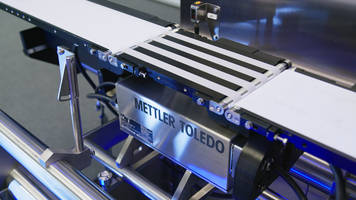

In addition, a new METTLER TOLEDO load cell - FlashCell™ - will be demonstrated on a C35 checkweigher. FlashCell enables the achievement of industry-leading throughputs at speeds of up to 800ppm. Systems with FlashCell are now able to process products more quickly and reduce product giveaway through greater weighing precision. Manufacturers will also benefit from smaller footprints to better fit equipment within limited factory floor space.

Specific to the pharmaceutical sector, the new T60 Integrated 360 Series provides serialization and aggregation of bottles and vials. The solution gives a 360-degree picture of a large range of round containers, enabling it to read and verify small product or serialization codes printed directly onto the bottle or on onto the applied labels.

METTLER TOLEDO will also demonstrate its connectivity and data management solutions. METTLER TOLEDO specialists will be available to explain and answer questions about the features and benefits of each solution in relation to the particular inspection challenge.

Robert Rogers, Senior Adviser of Food Safety and Regulations, will present "Requirements to Consider for Code Verification" on the Innovation Stage on Tuesday, September 28th, from 3:00pm -- 3:30pm in room C-2151. The talk will cover the "4 C's of Reliable Code Verification Solutions" that are needed to avoid unnecessary rework and product returns as well as the potential for potential fines, lawsuits and brand damage.

About METTLER TOLEDO Product Inspection Group

The Product Inspection division of METTLER TOLEDO is one of the leading providers within the field of automated inspection technology. The division includes the following brands: Safeline metal and X-ray inspection, Garvens and Hi-Speed checkweighers, and CI-Vision and PCE Track & Trace. The product inspection solutions improve manufacturers’ process efficiency and help them comply with industry standards and regulations. METTLER TOLEDO systems ensure consistently higher product quality, helping protect both consumers as well as the reputation of manufacturers and their products and brands.

Contacts:

Reader Inquiries:

Sarrina Crowley

METTLER TOLEDO Product Inspection

1571 Northpointe Parkway

Lutz, FL 33558 USA

Tel: +1-813-889-9500

PI.Marketing@mt.com

www.mt.com/pi

Editor Inquiries:

Cat McBride

McBride Public Relations

527 27th Street

Richmond, CA 94804 USA

Tel: +1-650-384-5727

connect@mcbridepr.com

www.mcbridepr.com