New Draft Survey Tool Determines Cargo Weight

Press Release Summary:

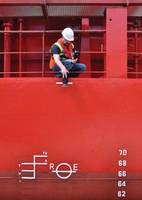

- Allows inspectors to measure, the draft mark readings for the weight determination on board a vessel

- Utilizes draft mark readings painted on the side of a vessel to determine the weight of the cargo

- Inspectors can measure from the safety of the ship deck with the accuracy of a digital tool

Original Press Release:

SGS Draft Survey Tool (DST) Improves 100-Year-Old Marine Measuring Method

New SGS DST an important invention in the sometimes risky world of vessel draft reading.

RUTHERFORD, NJ, Dec. 4, 2020 /PRNewswire/ - SGS, the world's leading testing, inspection and certification group is pleased to announce its Draft Survey Tool (DST) is now available for use in trade applications across North America. The DST is revolutionizing draft surveys as it is the only tool on the market that allows inspectors to measure, with more precision, the draft mark readings which are key for the weight determination on board a vessel while also ensuring inspector safety.

A draft survey is a method of cargo weight determination where the vessel's displacement figures in empty and loaded condition are recorded. The difference between both scenarios will determine the weight of the shipment loaded or unloaded from the vessel. The draft survey utilizes draft mark readings painted on the side of a vessel to determine the weight of the cargo. As a visual and subjective process, these marks had to be observed over time and from a distance in the water, from the deck of the vessel or from the port's quay, through precarious wind and wave swells. This could pose challenges when it came to safety of the inspector and accuracy of the readings.

However, the DST, through its digital readings, now allows inspectors to measure from the safety of the ship deck with the accuracy of a digital tool. This is a critical commercial requirement in today's complex transactions where a deviation of a single centimeter could result in a cargo weight overstatement or understatement by 100 metric tons or more, a significant cost that would have to be borne by either the shipper or the customer depending on the scenario.

Haritz Solachi, SGS Minerals Global Field Services Manager, invented the DST to address clients' needs for accuracy and cost control, while ensuring the safety of inspectors. "As an SGS surveyor, I know the inherent challenges in collecting this valuable data and wanted to find a way to increase the accuracy for the customer and minimize the risk to the inspectors. Before the invention of the DST and DST Lite, an inspector conducting a draft survey would need to visually assess and measure the draft marks of a vessel, at their empty and loaded state, often by taking a boat into difficult and risky conditions. There had to be a better way to enhance the process, improve the accuracy and help control customers' costs," said Solachi who took his patented, calibrated, and certified DST from concept to creation in two years.

Watch video here for more details

A by-product of this research and development was the creation of the DST Lite, a device that performs the same functions in limited and confined space such as between barges or in connection with smaller vessels. Using the latest technologies, the DST tools can be adapted to all vessel shapes, sizes and measuring points with an accuracy within two millimeters in 30 metres. It is this kind of accuracy that speaks to the reliability of this method.

The algorithm allows for the removal of all of the waves from the readings taken at the six measuring points on a vessel, which establishes the average of each reading point. The results are transmitted in real time to an APP on a surveyor's phone in the case of the DST Lite, or saved into the device in the case of the DST which replaces pencil and paper. All of the dot points needed to calculate the final draft in the device are saved in the APP and stored in the cloud.

"SGS prides itself on attending to and anticipating the needs of its customers as it has for over 100 years. The invention of the DST is another example of finding ourselves on the leading edge of innovation. In valuing the safety of our inspectors, we also found a way to enhance the service and improve the accuracy of the results for our customers," said Carlos Cordoba, SGS Trades Director – North America Minerals.

During more than 100 years the draft survey service was conducted in the same way without significant changes in the original procedure or technological developments that help the surveyors, until now with the SGS Draft Survey Tool.

About SGS

SGS is the world's leading inspection, verification, testing, and certification company. SGS is recognized as the global benchmark for quality and integrity. With more than 89,000 employees, SGS operates a network of over 2,600 offices and laboratories in 148 countries around the world.

SGS Canada Inc.

CONTACT: Fulvio Martinez, Head of Regional Communications, SGS North America, C: 281-714-6765, E: Fulvio.Martinez@sgs.com

Web Site: www.sgs.com/