New Delta-Dry and Lath 2-in-1 Rainscreen Solution for Dorken Systems For Stucco and Manufactured Stone Homes

Share:

Press Release Summary:

The new Delta-Dry rain-screen combined with a fiberglass lath from Dorken Systems is designed to prevent moisture and mold, wall rot, and decay in stucco and stone buildings. The product also helps to stop cracks, leaks, and falling stones.

Original Press Release:

Dörken Systems Inc. Launches New Delta®-Dry and Lath 2-in-1 Rainscreen Solution for Stucco and Manufactured Stone Homes

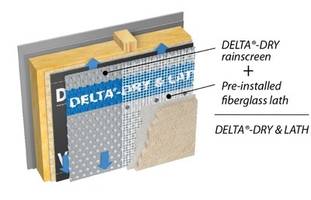

New product combines the proven technology of DELTA®-DRY with unique fiberglass lath for a one-step moisture-control solution

BEAMSVILLE, ON, Jan. 14, 2019 /CNW/ - Dörken Systems Inc., a leading manufacturer of high-performance air and moisture barriers, today announced the launch of new DELTA®-DRY & LATH. The new product takes on one of the building industry's biggest challenges, managing moisture to prevent mold, wall rot, and decay in stucco and manufactured stone buildings. DELTA®-DRY & LATH combines the proven technology of the DELTA®-DRY rainscreen with an innovative fiberglass lath to deliver a new one-step moisture-control solution. Dörken will be showcasing DELTA®-DRY & LATH at World of Concrete (WOC), Booth C3028, from January 22-25in Las Vegas as well as at the International Builders' Show (IBS), Booth SU3627, from February 19-21, also in Las Vegas.

"Stucco and manufactured stone buildings with wood-based sheathing have unique challenges when it comes to moisture. Without the proper moisture protection, long-term structural integrity is compromised," explained Marcus Jablonka, Vice President of Operations & Marketing at Dörken Systems Inc. "This was the inspiration behind DELTA®-DRY & LATH. The new system works to not only block solar-driven moisture from moving through the wall from the outside, but also gets rid of any moisture that originated from inside the house in the first place. This process of full ventilation paves the way for quicker drying, and helps to prevent moisture-related issues."

What makes DELTA®-DRY & LATH the unique 2-in-1 rainscreen solution on the market today is the added benefit of using a fiberglass lath instead of metal. First, installers are often prone to getting cuts when handling sharp metal, whereas handling fiberglass makes the installation safer, lighter, and smoother. Second, metal laths are known rust over time—creating visual staining and diminishing the aesthetic appearance in stucco and manufactured stone homes, and leaving the structures susceptible to cracks, leaks, and falling stones, along with overall moisture damage. The 2-in-1 benefit of DELTA®-DRY & LATH – the combination of the rainscreen and the fiberglass lath in one system – also means that an entire step is eliminated from the construction process. This reduces installation time and costs, while requiring fewer materials to apply the product.

"Our new moisture-protection solution is essential for builders and contractors who work with stucco and manufactured stone and are on the lookout to build to a higher standard and maintain long-term structural integrity," said Jablonka. "With DELTA®-DRY & LATH, structures are kept sound, call-backs are avoided, and clients are satisfied." In the end, occupant health and comfort are maintained, and the reputation of the builder is kept intact.

Visit DELTA®-DRY & LATH's product page, and to learn about moisture challenges with stucco and stone, read our blog. Visit Dörken at IBS and WOC in 2019 to speak to the Dörken team directly and to learn more about the product that's revolutionizing the industry.

About Dörken Systems Inc.

Dörken is the North American division of Ewald Dörken AG in Germany. Ewald Dörken AG has been in business since 1892, longer than almost any building materials company. For more than 125 years, Dörken has been delivering innovative, high-performance air and moisture barriers for both commercial and residential construction, protecting all types of buildings from around the world in the most extreme weather conditions. Visit Dörken's website, Twitter and LinkedIn for more information.