New b.triton Roller Chains are Resistant to Corrosion

Press Release Summary:

- Used in a temperature range from -10°C to +130°C and also extended to 150°C by using an alternative high-temperature lubricant

- Made from RoHS-compliant materials and free from hexavalent chromium (CrVI)

- Ideal for use in high corrosive environments requiring characteristically high fatigue strength and tensile strength of carbon steel chains

Original Press Release:

High-Tech Coating Protects Against Corrosion and Wear: The New B.Triton High-Performance Roller Chains from Iwis

Wherever chains are exposed to the effects of seawater, or subject to stringent cleaning requirements, materials with conventional coatings soon reach their technical limits: roller chains used in harbours, or applications in the food or building services industry, rapidly lose their wear- and corrosion-resistant properties. The new b.triton series from Munich-based chain manufacturer iwis – high-performance roller chains with an innovative combination of coatings – is the perfect product for use in harsh operating environments.

High-performance zinc flake technology is combined with a special surface treatment, ensuring that JWIS b.triton chains are more resistant to corrosion than comparable competitor products in the market, as shown by the results of standardised corrosion tests. The new roller chains are highly sustainable, so they are particularly environment-friendly, especially as they are made from RoHS-compliant materials and free from hexavalent chromium (CrVI).

The basis of the newly developed chains is the strength of carbon steel combined with special surface coatings. This technology means the chains are ideal for use in highly corrosive environments requiring the characteristically high fatigue strength and tensile strength of carbon steel chains. A particular feature of the special zinc flake coating is its extremely good adhesion to the base material, which guarantees reliable protection of the roller chain against corrosion – even under the toughest operating conditions. An additional salt spray test with chains already in operational use confirmed that the chain is reliably protected against corrosion.

Special coatings on bushes and pins reduce wear in JWIS b.triton chain bearings. Extruded bushes and rollers guarantee even better corrosion resistance, reduced run-in elongation and quieter chain running. The new lubricant “iwiDUR G”, which was specially developed for the applications in which b.triton chains are used, provides additional protection against wear and corrosion. As a result, JWIS b.triton chains can be used in a temperature range from -10 °C to +130 °C – which can be extended to 150 °C by using an alternative high-temperature lubricant.

Munich-based chain manufacturer iwis offers a wide range of products for all drive and conveyor technology applications. The comprehensive product portfolio includes precision and high-performance roller chains, conveyor chains, maintenance-free and corrosion-proof chains, accumulation chains, conveyor chains for special applications, leaf chains, flat-top chains, hollow pin chains, pin oven chains and tube conveyor chains, chains and accessories for agricultural machinery, and timing chain drive systems for the automotive industry.

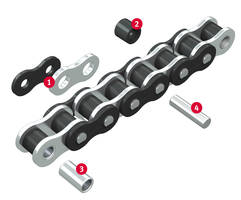

Specially coated individual parts of the b.triton chain support its durability.

- b.triton inner and outer chain plates (lupper left): High-performance coating provides outstanding corrosion protection

- b.triton bushes (upper right): Manufactured by extrusion and with a special wear-reducing coating to provide protection against media penetration and rust

- b.triton rollers (bottom left): Seamless components and special coating ensure quiet chain running and corrosion protection

- b.triton pins (bottom right): Corrosion protection in combination with optimum wear running properties

iwis is a leading supplier of precision chain systems for drive and conveyor applications. The company is active in the following fields:

- iwis motorsysteme makes chains and timing drives for the automotive industry.

- iwis antriebssysteme produces precision roller and conveyor chains for industrial applications in general machine engineering, plant engineering, the packaging, printing and food industries and conveyor technology.

- iwis smart connect makes housings and installation frames, as well as producing high-precision stamped/bent sheet metal parts, particularly for the fields of electrical connections, press-fit technology, IDC technology and MCS contact technology.

- THIEN eDrives: Electromobility and electric motors

The family company was founded in 1916 and is now managed in the fourth generation by Johannes Winklhofer

iwis has a global workforce of more than 2,100 and aims to achieve a turnover of 500 million euros in 2019. Besides its production plants in Germany (Munich, Landsberg, Wilnsdorf, Sontra, Kaufbeuren and Rieden) and in China, the USA and the Czech Republic, it has subsidiaries in various European and overseas countries, including Brazil, the UK, France, India, Italy, Canada, Korea, Switzerland, Singapore and South Africa. iwis is represented at a total of 45 locations worldwide.

Contact:

iwis drive systems, LLC

Building 100, 8266 Zionsville Road

IN 46268 Indianapolis USA

Kody Fedorcha

Phone: +1 317 821 3539

sales@iwisusa.com

http://www.iwisusa.com/